The sanding machine conveyor belt is one of the most critical components that directly affects surface flatness, smoothness, and overall finishing quality after sanding. Selecting the correct PVC abrasive conveyor belt for each sanding machine model and workpiece type not only improves sanding efficiency but also reduces wear, minimizes material slippage, and optimizes long-term operating costs. This article will help you clearly understand the structure, technical characteristics, common types of drum sander conveyor belts, and their practical applications in manufacturing.

What Is a Sanding conveyor belt?

A drum sanding machine conveyor belt is a specialized belt installed inside drum sanders or wide belt sanding machines. Its primary function is to transport and firmly hold the workpiece throughout the sanding process. This belt is subjected directly to the pressure of sanding drums, making it a decisive factor in surface flatness, uniformity, and final product quality.

Unlike standard infeed conveyor belts, wide belt sander conveyor belts require:

- Excellent flatness

- High abrasion resistance

- Stable grip

- Low elongation

These properties ensure the workpiece does not slip, vibrate, or shift dimensionally during sanding.

Technical Specifications of PVC Conveyor Belts for Sanding Machine

- Belt type: Abrasive PVC conveyor belt for wood sanding machines

- Surface: Square-pattern / black diamond texture – enhanced grip

- Material: PVC (Polyvinyl Chloride)

- Total thickness: Approx. 8.5 mm (including abrasive top layer)

- Operating temperature: -15°C to +80°C

- Noise reduction: No

- Tensile force at 1% elongation: 30 N/mm

- Antistatic properties: No

- Minimum pulley diameter: 150 mm

- Fire-resistant transverse fabric: No

Advantages of Drum Sander Conveyor Belts

Drum sander conveyor belts are specially designed to operate under continuous sanding pressure, offering significant advantages over standard conveyor belts:

- High Grip – Anti-Slip Performance: The abrasive surface generates high friction, keeping wood or material firmly in place, preventing vibration and misalignment.

- Consistent Surface Flatness: With high flatness and low elongation, the belt ensures smooth and even movement through the sanding drum, resulting in superior surface quality and fewer defects.

- High Abrasion Resistance: Designed to withstand continuous friction, these belts are suitable for multi-shift, long-term industrial operation.

- Compatible with Various Materials: Suitable for MDF, HDF, plywood, veneer, solid wood, composite materials, and thin metal sheets.

- Stable Operation – Reduced Downtime: Stable grip and reinforced construction minimize belt slipping, stretching, and misalignment, reducing maintenance time and machine adjustments.

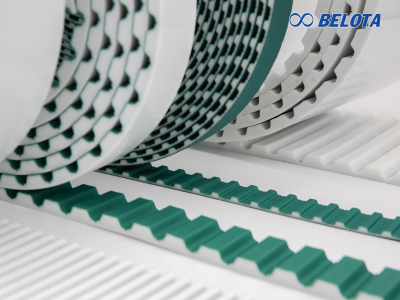

Common Types of Drum Sander Conveyor Belts

In drum sanding and wide belt sanding machines, PVC conveyor belts are mainly used for material feeding and guiding, with different surface textures to enhance grip and stability.

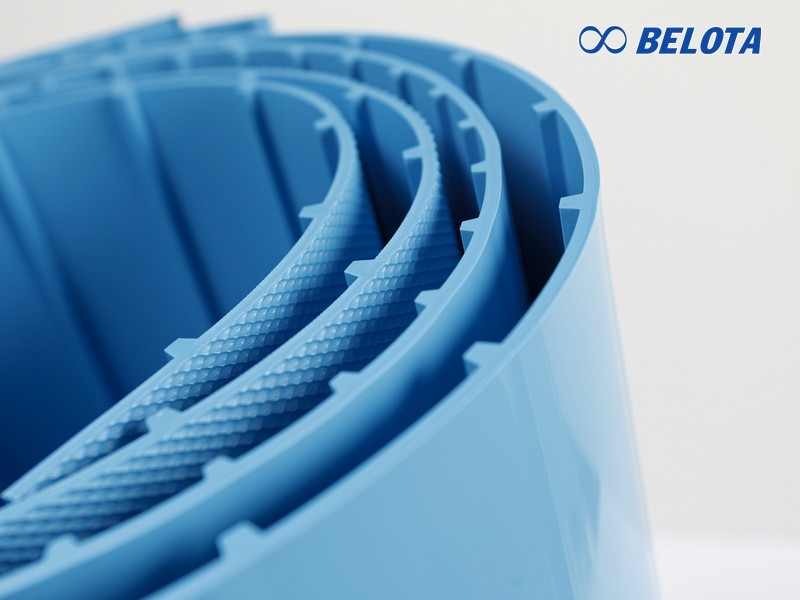

PVC Diamond (Herringbone) Conveyor Belt

The most widely used belt for drum sanding machines. The diamond or square-pattern surface improves friction, keeping workpieces stable as they pass through the sanding zone. Ideal for small to medium-capacity sanding machines.

PVC Spike-Textured Conveyor Belt

Featuring raised spike or pyramid-shaped patterns, this belt provides excellent grip for smooth surfaces such as veneer or pre-coated wood. Suitable for moderate-speed feeding but not recommended for prolonged heavy pressure due to faster surface wear.

Coarse Abrasive PVC Conveyor Belt

Designed with a rough abrasive surface for thick or heavy workpieces. Offers strong grip even on uneven surfaces. However, it may leave slight impressions on soft wood or high-finish materials.

PVC Square-Pattern Conveyor Belt

The Square-pattern PVC conveyor belts enhances friction while maintaining smooth material transport. It reduces slipping and vibration, ensuring stable movement under sanding drums. Commonly used in small to medium-capacity drum sanders for MDF, plywood, veneer, and solid wood.

Applications of Drum Sander Conveyor Belts

Drum sander conveyor belts are widely used in industries requiring flat, uniform, and high-precision surface finishing.

- Wood Processing & Furniture Manufacturing:The most common application. The belt transports MDF, HDF, plywood, veneer, and solid wood through sanding machines. Belt quality directly affects surface smoothness and consistency.

- Engineered Panels & Decorative Materials: Used in sanding processes for plywood, melamine-coated boards, laminate, and decorative veneers. The belt must provide stable grip without scratching the surface.

- Thin Metal Sheets & Composite Materials: In some sanding lines for aluminum, stainless steel, or composite materials, conveyor belts hold the workpiece steady during deburring and surface finishing. High abrasion resistance is essential in this application.

- Handicrafts & Specialty Materials: Drum sanders are used to prepare surfaces before painting or coating handcrafted wood products and specialty materials. Conveyor belts help control feed speed and ensure uniform surface quality.

Frequently Asked Questions (FAQs)

What materials are drum sander infeed conveyor belts made of?

Most commonly abrasive PVC belts (diamond, square-pattern, spike-textured) due to high grip and cost efficiency. Heavy-duty machines may use rubber or PU belts.

Are PVC drum sander belts different from standard PVC conveyor belts?

Yes. They are thicker, have deeper abrasive surfaces, higher abrasion resistance, and greater tensile strength than standard packaging or logistics belts.

When should a drum sander belt be replaced?

Replace the belt when the abrasive surface becomes smooth, the belt stretches, cracks, delaminates, or when workpieces frequently slip during operation.

Can drum sander conveyor belts be customized?

Yes. Belts can be fabricated to specific widths, lengths, thicknesses, and surface patterns to match each sanding machine model.

Trusted Supplier of Sanding Machine Conveyor Belt

Stable operation, long-lasting performance, and international safety standards – Belota's sanding machine conveyor belt are the preferred choice for modern manufacturing plants. We offer:

✅ Durable & reliable quality – Specialized abrasive PVC belts (diamond, square-pattern, spike-textured) designed to withstand sanding pressure and friction.

✅ Excellent grip & smooth operation – Ensures stable workpiece movement, reducing slippage and improving surface quality.

✅ Custom fabrication for each machine model – Tailored belt width, loop length, thickness, and surface texture.

✅ Low elongation – minimal adjustment – Reinforced fabric structure reduces stretching during continuous operation.

✅ Optimized for woodworking environments – Performs reliably under dust and operating temperatures of sanding machines.

✅ Professional technical consultation – Correct belt selection based on machine capacity, material type, sanding pressure, and speed.

✅ Fast installation & nationwide support – Precision belt joining and installation guidance to minimize downtime.

✅ Cost-effective long-term solution – Extended belt lifespan reduces replacement and maintenance costs.

📞 Contact Belota today: +84 917 657 946 for expert consultation and the most suitable conveyor belt solution for your sanding line.

Related reference: PVC Conveyor Belt Price List – Free Technical Consultation