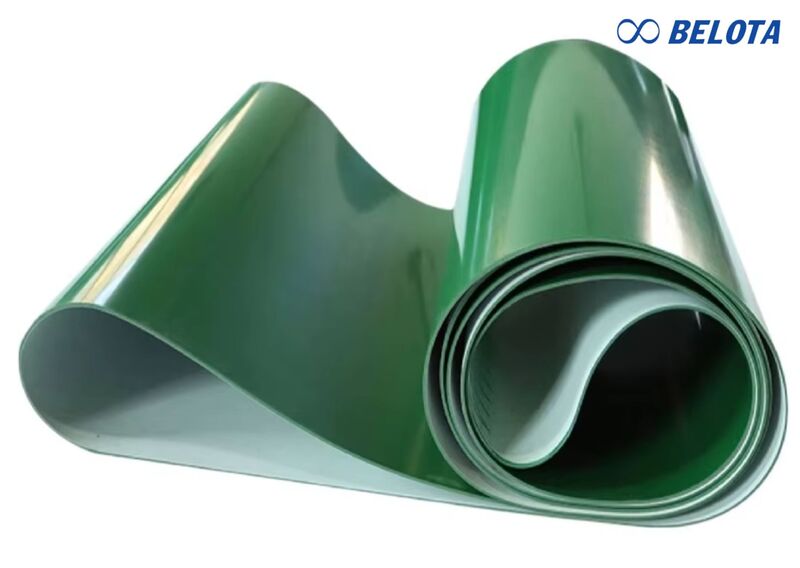

PVC anti-static conveyor belts are specialized conveying solutions designed for production lines that require strict electrostatic discharge (ESD) control, helping protect sensitive components, equipment, and improve overall operational safety. With effective static dissipation, high durability, and cost efficiency, this conveyor belt is widely used in electronics manufacturing, cleanrooms, printing, packaging, and industrial automation.

What Is a PVC Anti-Static Conveyor Belt?

A PVC anti-static conveyor belt is manufactured from PVC material compounded with anti-static (ESD) additives, which help reduce and eliminate surface static electricity generated during operation. This type of conveyor belt is specifically designed for environments where electrostatic control is critical, ensuring product and equipment safety.

Thanks to its ability to conduct and dissipate static charges, PVC anti-static conveyor belts minimize risks such as static sparks, dust attraction, fine particle adhesion, and damage to sensitive electronic components. They are an essential solution in modern production lines where safety and operational stability are top priorities.

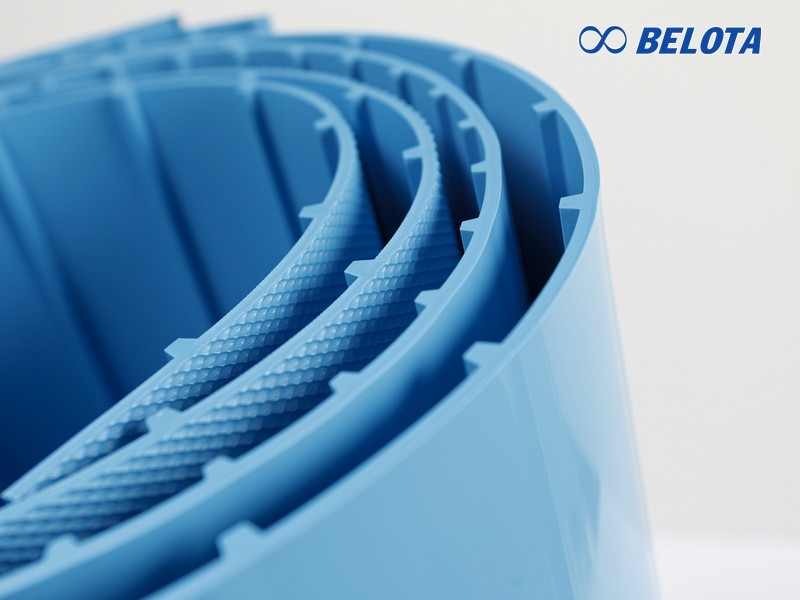

Structure of PVC Anti-Static Conveyor Belts

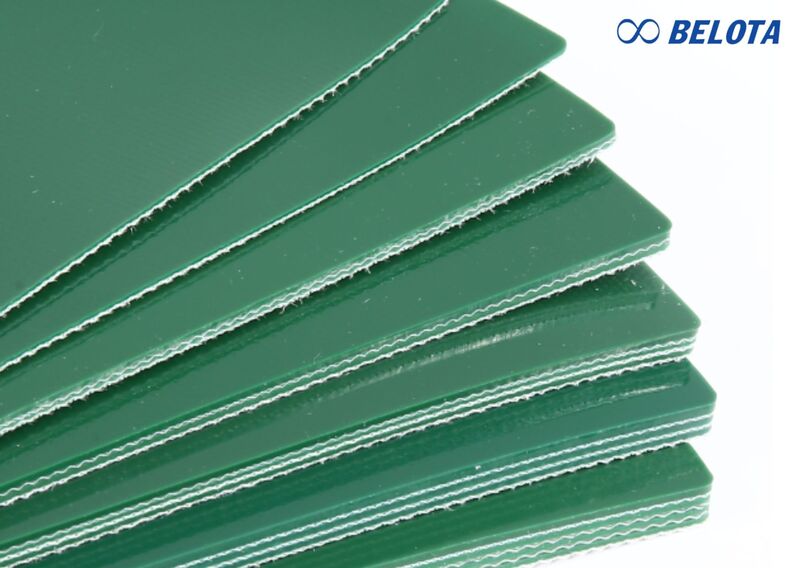

PVC anti-static conveyor belts are composed of multiple specialized layers to ensure stable conveying performance while maintaining effective static control throughout operation. The basic structure includes:

- Top Layer: Made from PVC material compounded with anti-static / ESD additives, this layer disperses and neutralizes surface static electricity, preventing charge buildup when in contact with products. It is the primary conveying surface.

- Middle Layer: Typically constructed from polyester (EP) fabric or specialized synthetic fibers integrated with carbon fibers or conductive additives. This layer acts as a conductive bridge, transferring static charges from the top surface to the bottom layer, ensuring safe and stable static dissipation during operation.

- Bottom Layer: Manufactured from synthetic rubber or wear-resistant conductive fabric, this layer conducts static electricity to ground through the conveyor frame and rollers, supporting continuous and effective static discharge—especially in ESD-sensitive environments.

See Also: Green PVC Conveyor Belts – Durable & Stable | BELOTA

Key Technical Features of PVC Antistatic Conveyor Belt

PVC antistatic conveyor belt are engineered for production lines requiring precise electrostatic control. Key advantages include:

Active Static Control

Anti-static additives, carbon fibers, or conductive layers prevent static charge accumulation, safely dissipating electricity through the conveyor system—unlike standard PVC belts, which are prone to static buildup.

ESD-Compliant Surface Resistance

Surface resistance is maintained within 10⁶ – 10⁹ Ω, meeting the requirements of electronics assembly lines, cleanrooms, and sensitive component handling. This property is inherent to the material and does not degrade quickly over time.

Stable Operation with Reduced Dust Attraction

By minimizing static electricity, these belts attract significantly less dust, plastic particles, and metal debris, helping maintain a cleaner production environment and reducing maintenance costs.

Protection for High-Value Products and Equipment

Reduced static discharge protects PCBs, chips, electronic components, and measuring devices—a level of safety standard PVC conveyor belts cannot provide in ESD environments.

Technical Specifications of PVC Anti-Static Conveyor Belts

Typical specifications for PVC anti-static conveyor belts used in ESD-controlled production lines include:

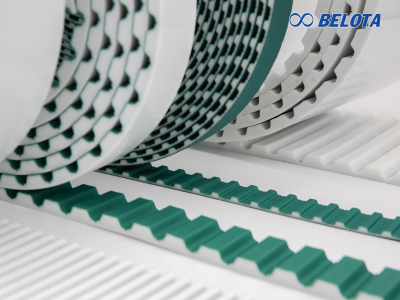

- Belt Material: PVC or PU (depending on application requirements)

- Color: Black, Green

- Thickness: 1 mm / 2 mm / 3 mm / 4 mm

- Fabric Plies: 1 / 2 / 3 / 4 layers

- Surface Type: Smooth, matte, or chevron (anti-slip)

- Minimum Pulley Diameter: ≥ 30 mm

- Tensile Strength at 1% Elongation: Suitable for light to medium-duty industrial applications

- Breaking Strength: Approx. 120 N/mm

- Operating Temperature: -10°C to +80°C

- Belt Weight: Approx. 2.3 kg/m² (depending on thickness and construction)

- Typical Applications: Electronics, component assembly, cleanrooms, printing, packaging, engineering plastics

Advantages of PVC ESD Conveyor Belt

PVC ESD conveyor belt are widely adopted due to their effective static control and cost efficiency. Key benefits include:

- Stable anti-static performance through integrated ESD additives

- Protection of sensitive electronic components such as PCBs, chips, and sensors

- Reduced dust adhesion, maintaining cleaner production lines

- High mechanical strength and stable operation with EP fabric reinforcement

- Cost-effective solution, easier installation and replacement compared to PU ESD belts

- Flexible Applications Across Industries

PVC Electrostatic Discharge Conveyor Belt are widely used in

- Electronics & component manufacturing: assembly, inspection, and packaging

- Cleanroom environments: strict dust and ESD control

- Printing & packaging: reduced paper sticking and ink contamination

- Engineering plastics: minimizing particle adhesion

- Industrial assembly & automation: stable and safe conveying

- Logistics & high-tech product packaging: safe handling of ESD-sensitive goods

Criteria for Choosing High-Quality PVC Anti-Static Conveyor Belts

When selecting PVC anti-static conveyor belts, consider the following:

- ESD Performance: Ensure surface resistance complies with 10⁶ – 10⁹ Ω for long-term, stable static control.

- Material and Construction: Verify the presence of conductive fibers or carbon layers, high-quality anti-static PVC compounds, and suitable EP fabric plies for your load requirements.

- Manufacturing Quality and Certification: Choose products with clear quality control, testing standards, and reputable suppliers offering technical support and after-sales service. Avoid overly cheap products with poor ESD performance. Prioritize durability and low maintenance cost for optimal long-term value.

Frequently Asked Questions

1. How does a conductive conveyor belt differ from a standard PVC conveyor belt?

Conductive conveyor belts feature ESD-compliant surface resistance, reducing static discharge, dust attraction, and protecting sensitive components—unlike standard PVC belts.

2. Does PVC anti-static conveyor belt meet ESD standards?

Yes. High-quality PVC anti-static belts maintain surface resistance between 10⁶ – 10⁹ Ω, suitable for industrial ESD environments.

3. Is an anti-static conveyor belt durable?

Yes. When properly selected, it offers high mechanical strength, abrasion resistance, and stable anti-static performance throughout its service life.

4. Can ESD conveyor belts be customized?

Yes. Belts can be cut to size, hot-spliced, mechanically joined, and fitted with guides or sidewalls while maintaining ESD properties.

5. When should PVC anti-static belts be chosen instead of PU anti-static belts?

Choose PVC when:

- High temperature resistance is not required

- Cost efficiency is a priority

- Applications involve light to medium loads

For stricter hygiene or higher temperature demands, PU anti-static belts are recommended.

Trusted Supplier of PVC Anti-Static Conveyor Belts

Stable operation, durable performance, and international safety standards — Belota PVC Anti-Static Conveyor Belts are the ideal choice for modern factories.

We offer:

✔ Genuine quality materials & long service life

✔ Optimized performance with reduced wear

✔ Flexible customization (size, surface, tensile strength)

✔ Safe for electronics, food, and pharmaceutical applications

✔ Expert technical consulting

✔ Fast installation & nationwide support

✔ Long-term operational efficiency

✔ Made-to-order solutions for all conveyor systems

📞 Contact Belota today: +84 917 657 946 for professional consultation and the best conveyor belt solution for your production line.

Related Reference: PVC Conveyor Belts – Full Range | Pricing & Technical Support