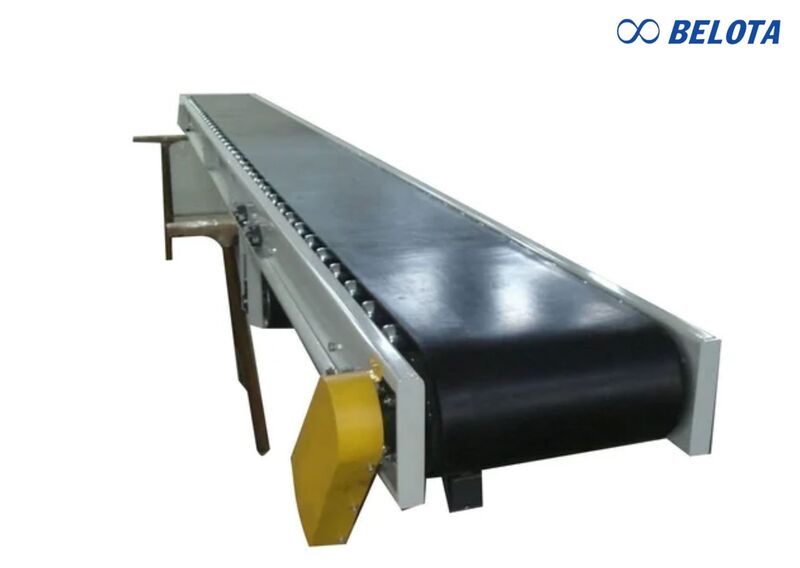

Smooth rubber conveyor belts are one of the most widely used industrial conveyor belt types, especially in systems handling bulk materials and heavy loads. Depending on the required load capacity, conveying distance, and operating conditions, businesses can select the appropriate EP fabric rating ranging from EP100 to EP500 to ensure high tensile strength, minimal elongation, and optimal operational efficiency.

Currently, smooth rubber conveyor belts are available in a wide range of standard specifications, with belt widths from B300 to B2000, 3 to 6 fabric plies, and thicknesses ranging from 7 mm to 20 mm. These options allow the belts to meet the needs of both small-scale production lines and heavy-duty industrial conveyor systems. In this article, Belota provides a comprehensive overview to help you choose the most suitable smooth rubber conveyor belt for your application.

What Is a Smooth Rubber Conveyor Belt?

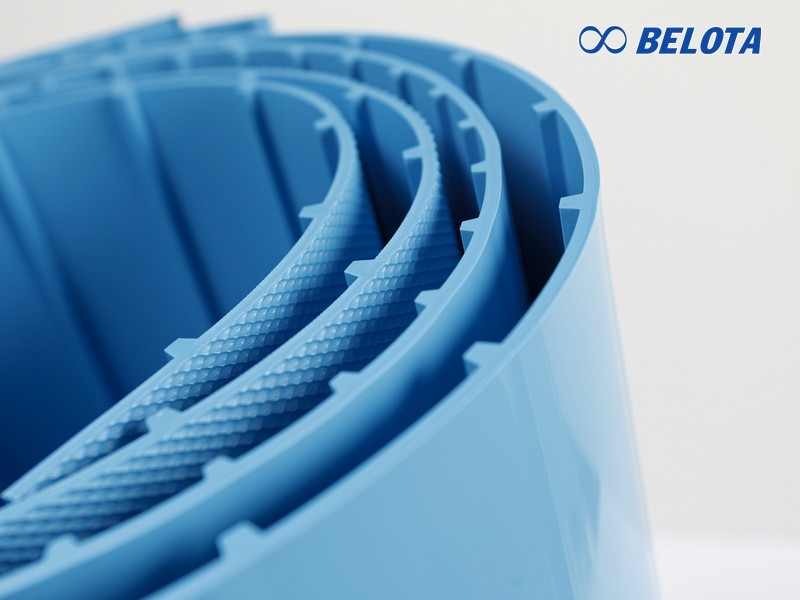

A smooth rubber conveyor belt is a type of conveyor belt with a completely flat surface, without cleats, ribs, or textured patterns. It is manufactured from natural or synthetic rubber compounds and reinforced with high-strength fabric plies.

This belt type is specifically designed for conveying materials on flat surfaces or low-incline conveyors (typically below 18°).

Structure of a Smooth Rubber Conveyor Belt

Top Rubber Cover

-

Material: High-quality natural or synthetic rubber

-

Function: Direct contact with conveyed materials

-

Design options based on application:

-

Abrasion-resistant (for sand, stone, minerals)

-

Oil- and chemical-resistant (for agricultural products, food processing, or industrial chemicals)

-

Fabric Reinforcement Layer

-

EP Fabric (Polyester – Nylon): The most commonly used type today. Offers very low elongation, excellent impact resistance, and resistance to moisture and mildew.

-

NN Fabric (Nylon – Nylon): Highly flexible with superior tensile strength, suitable for long-distance conveyors and heavy-load applications.

-

CC Fabric (Cotton): Less commonly used, mainly for special environments requiring high rubber-to-fabric adhesion.

Bottom Rubber Cover

-

Characteristics: Thinner than the top cover

-

Function: Contacts the drive pulley and idlers, providing sufficient friction for effective power transmission while protecting the internal fabric layers from mechanical wear.

Standard Technical Specifications

-

Rubber compound: SBR (standard), Neoprene, Nitrile (oil & chemical resistant)

-

Color: Black

-

Number of plies: 2 – 6 plies (EP or NN fabric)

-

Belt thickness: 3 – 16 mm (depending on load requirements)

-

Belt width: 300 – 1200 mm (B300 – B1200)

-

Surface hardness: 75 ± 5 Shore A

-

Tensile strength: ≥ 15 MPa (2175 PSI)

-

Operating temperature: -20°C to 100°C

-

Roll length: Up to 300 m

-

Surface finish: Smooth, flat

-

Chemical resistance: Resistant to saltwater, oils, solvents, and mild acids

Key Advantages of Smooth Rubber Conveyor Belts

-

High load capacity: Reinforced EP/NN fabric ensures stable transport of heavy materials such as coal, sand, stone, and ore without excessive stretching or deformation.

-

Excellent abrasion resistance: High-quality rubber compounds provide long service life under continuous friction.

-

Easy installation & maintenance: Flat surface design simplifies belt alignment, cleaning, and replacement, minimizing downtime.

-

Chemical & environmental resistance: Available in specialized rubber compounds for oil resistance, waterproofing, and chemical exposure.

-

Cost-effective investment: One of the most economical conveyor belt solutions while maintaining high productivity.

-

Easy cleaning: Smooth surface allows quick removal of dust and residual materials.

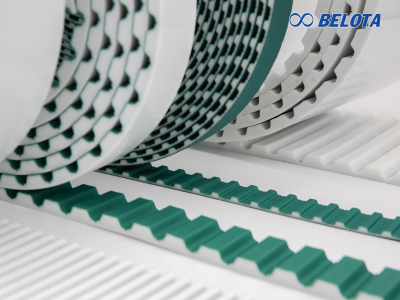

Common Types of Smooth Rubber Conveyor Belts

Based on operating conditions, Belota supplies four main types:

-

Heat-resistant rubber conveyor belts: Designed for high-temperature materials, commonly used in cement plants, thermal power plants, kilns, and clinker handling systems.

-

Oil- & chemical-resistant conveyor belts: Made from special rubber compounds to prevent swelling and degradation caused by oils and chemicals. Widely used in oil & gas, fertilizer, and food processing industries.

-

Anti-static rubber conveyor belts: Engineered to dissipate static electricity and prevent sparks, making them essential for coal mines and explosive dust environments.

-

Impact- & abrasion-resistant conveyor belts: Featuring thick, tough rubber covers for transporting sharp, heavy materials such as large stones, mineral ores, and metal scraps.

Related reference: Heat-Resistant Rubber Conveyor Belts | Belota

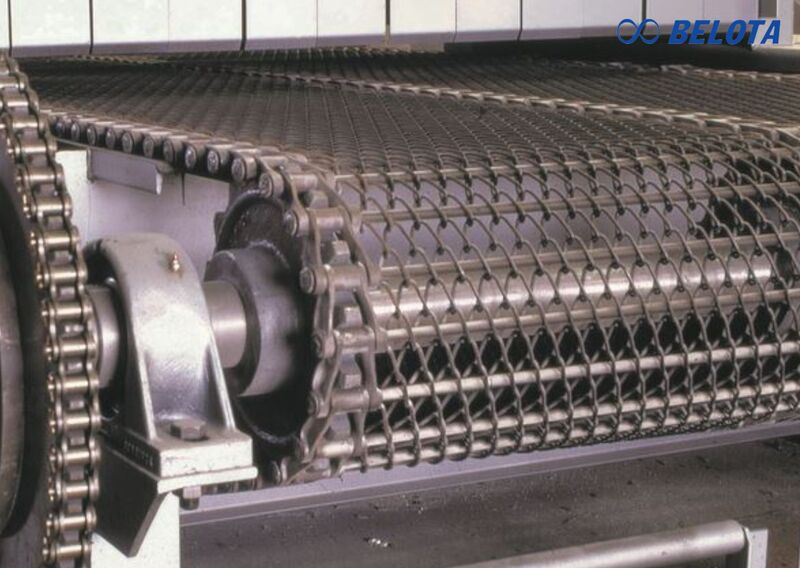

Applications of Smooth Rubber Conveyor Belts

Thanks to their high load capacity and economic efficiency, smooth rubber conveyor belts are widely used in:

-

Mining & construction: Conveying coal, sand, gravel, stone, ore, and cement.

-

Agriculture: Transporting rice, corn, coffee beans, pepper, and animal feed in milling plants and silos.

-

Heavy industry: Handling raw materials such as fertilizers, chemicals, wood chips, and pulp.

-

Logistics & warehousing: Bulk material handling at ports, warehouses, and industrial storage facilities.

How to Select & Use the Right Smooth Rubber Conveyor Belt

-

Material characteristics: Consider weight and sharpness to determine rubber cover thickness (typically 3–6 mm) and number of plies.

-

Operating environment: Choose suitable rubber compounds—heat-resistant (HR), oil-resistant (OR), or standard SBR.

-

Fabric selection: EP fabric is recommended due to its low elongation, reducing frequent belt re-tensioning.

-

Pulley compatibility: Ensure pulley diameter matches belt thickness to prevent fabric damage or delamination.

-

Belt width: Select standard widths (B500, B600, B800, B1000, etc.) based on material flow rate.

-

Regular maintenance: Inspect belt joints, clean idlers, and adjust belt tracking to prevent edge wear and misalignment.

Trusted Supplier of Smooth Rubber Conveyor Belts

Smooth rubber conveyor belts are an efficient solution for transporting bulk materials and heavy loads in industrial conveyor systems. With high durability, excellent load capacity, and stable operation, Belota is committed to delivering:

-

High load capacity with reinforced EP/NN fabric

-

Superior abrasion resistance for coal, stone, sand, and ore

-

Stable performance on flat and low-incline conveyors (≤18°)

-

Custom rubber compounds: heat-resistant, oil-resistant, anti-static

-

Custom manufacturing: thickness, width, plies, and belt length

-

Easy installation & maintenance to reduce downtime

-

Long service life and optimized operating costs

📞 Contact Belota at +84 917 657 946 for professional consultation and the best conveyor belt solution for your system.

Related reference: Rubber Conveyor Belts | High Quality Industrial Solutions | Belota