V-type chevron rubber conveyor belts are a specialized conveying solution designed for inclined conveyor systems, effectively preventing material slippage while maintaining stable productivity under heavy-load conditions. Thanks to the molded V-shaped cleats on the belt surface, this belt type is widely used in agriculture, construction, mining, and logistics industries.

This article will help you clearly understand the structure, advantages, classifications, real-world applications, as well as key considerations when designing and installing V-type chevron rubber conveyor belts to achieve optimal operating efficiency.

What Is a V-Type Chevron Rubber Conveyor Belt?

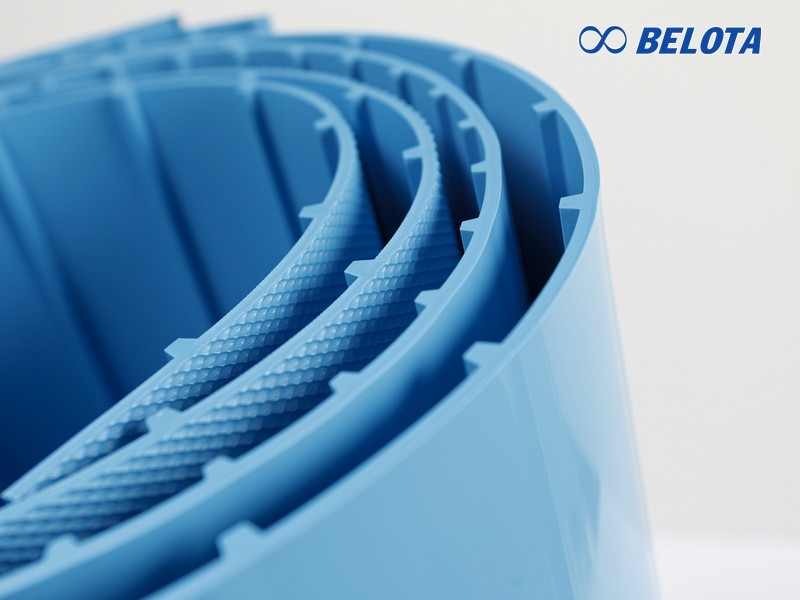

A V-type chevron rubber conveyor belt is a special rubber belt featuring V-shaped cleats molded directly onto the surface. This design significantly increases friction, allowing materials both bulk and bagged to be conveyed on steep inclines without slipping or rolling back, ensuring maximum system efficiency.

Technical Specifications

-

Belt material: Black rubber

-

Standard belt widths: B500, B600, B650, B800, B1000, B1200

-

Belt thickness:

-

3P × 7 mm

-

4P × 8.5 mm

-

4P × 9 mm

-

5P × 10 mm

-

6P × 12 mm

-

-

Chevron (V-cleat) height: 5, 10, 15, 20, 25, 30 mm

-

Motor power: 0.4 kW – 3.2 kW

-

Frame: Heavy-duty steel frame with powder coating

-

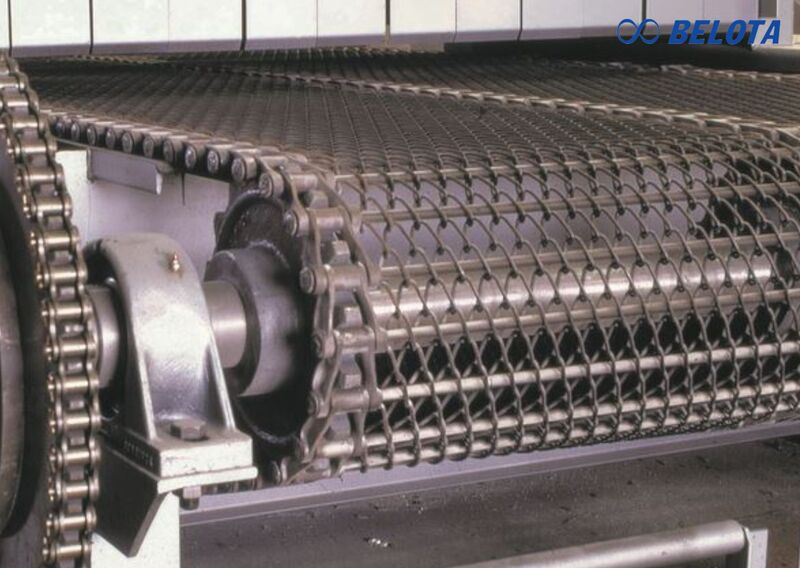

Drive system: Chain drive or V-belt (pulley) drive

-

Drive pulley: Galvanized steel or stainless steel; Ø89, Ø102, Ø133 mm

-

Carrying rollers: Galvanized steel or stainless steel; Ø32, Ø38, Ø50, Ø60 mm

-

Control system: Variable frequency drive (VFD), emergency stop button, ON/OFF power switch

Related reference: Smooth Rubber Conveyor Belts for Heavy-Duty Conveying

Key Advantages of V-Type Chevron Rubber Conveyor Belts

-

Excellent anti-slip performance: Molded V-shaped cleats ensure stable conveying on steep inclines ranging from 22° to 40°.

-

High strength & abrasion resistance: Multi-ply EP fabric combined with thick rubber covers provides excellent impact resistance and tear strength.

-

Stable heavy-load conveying: Smooth operation under high capacity without material spillage or belt deformation.

-

Low elongation: Polyester fabric reinforcement maintains elasticity while minimizing excessive stretching under harsh conditions.

-

Cost-effective investment: Simple structure, easy maintenance, and convenient component replacement help reduce long-term operating costs.

-

Adaptable to harsh environments: Resistant to moisture, weather exposure, and mild chemicals.

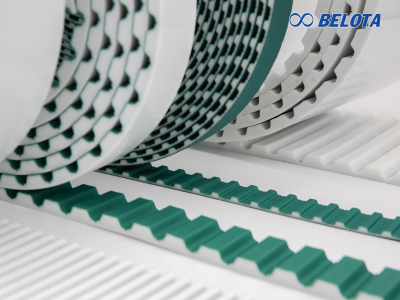

Common Types of V-Type Chevron Rubber Conveyor Belts

Fixed V-Type Chevron Conveyor Belt

-

Purpose: Continuous conveying of cartons, bags, and bulk materials between production stages.

-

Advantages: Low investment cost, extremely rigid structure, high durability, and long-term operational stability.

Mobile V-Type Chevron Conveyor Belt

-

Purpose: Loading goods onto trucks, containers, or conveying materials to elevated positions.

-

Advantages: Equipped with wheels and electric/hydraulic lifting systems, capable of operating at inclines up to 35° without slippage.

Important Considerations for Design & Installation

Design & Material Selection

-

Belt width & cleat configuration: Select belt width (B500, B600, B800, etc.) according to load capacity. Leave sufficient edge clearance for side guides or rubber skirts to avoid cleat damage.

-

Rubber properties: Choose EP rubber with appropriate abrasion resistance, oil resistance, or heat resistance depending on the operating environment.

-

Belt strength: The number of fabric plies must match belt length and load capacity to prevent excessive elongation or internal belt failure.

Power Calculation & Electrical System

-

Load determination: Accurately calculate material weight to select suitable motor power, pulley size, and frame thickness.

-

Motor optimization: Using a VFD allows flexible speed control, soft starting, motor protection, and energy savings.

Installation & Safe Operation

-

Maintenance clearance: Provide at least 50 cm of access space on both sides of the conveyor for inspection, lubrication, and periodic maintenance.

-

Roller alignment accuracy: Roller diameter and length must match the belt width; precise alignment prevents vibration and uneven wear.

-

Incline optimization: For slopes above 22°, V-type belts with cleat heights of 15–30 mm are required to prevent material rollback.

Practical Applications

V-type chevron rubber conveyor belts are an ideal solution for inclined conveying across multiple industries:

-

Agriculture: Transporting nuts, seeds, coffee beans, rice, corn, and round-shaped food products.

-

Construction: Conveying sandbags, cement bags, bricks, stones, and concrete mixtures to elevated areas.

-

Heavy industry & mining: Handling coal, ore, and irregular bulk materials on inclined terrain.

-

Logistics & warehousing: Widely used in mobile conveyors for loading cartons and bags onto trucks and containers.

-

Wood chip & paper processing: Conveying wood chips, bark, and dry pulp between height-differentiated stages.

Market Price Reference for V-Type Chevron Rubber Conveyor Belts

The following prices are for reference only and may vary depending on belt specifications, rubber grade, number of plies, and project requirements. Please contact suppliers for accurate quotations.

| Specifications | Reference Price (VND/meter) |

|---|---|

| Width 400–800 mm, standard V-cleats | 300,000 – 550,000 |

| Width 500 mm, complete system (frame + motor) | ~45,850,000 (full conveyor) |

| Width 400–800 mm (various grades) | 450,000 – 1,200,000 |

| Width 800 mm, 4-ply, heat-resistant | 500,000 – 1,500,000 |

Reliable Supplier of V-Type Chevron Rubber Conveyor Belts

V-type chevron rubber conveyor belts are a highly effective solution for conveying heavy materials and bulk goods in industrial conveyor systems. Belota is committed to providing:

✅ Excellent anti-slip performance on inclined conveyors – Molded V-cleats ensure stable conveying at slopes up to 30–40° (depending on cleat height).

✅ Heavy-load capability & durable structure – Multi-ply EP/NN fabric core with thick rubber covers minimizes elongation and deformation.

✅ High abrasion resistance – Ideal for coal, stone, sand, and ore handling.

✅ Stable operation with minimal spillage – Maintains consistent productivity and reduces material loss.

✅ Specialized rubber options – Heat-resistant, oil-resistant, and anti-static grades available.

✅ Custom fabrication – Thickness, width, number of plies, and belt length tailored to requirements.

✅ Easy installation & maintenance – Reduced downtime and maintenance costs.

✅ Long service life & high ROI – Optimized long-term operational efficiency.

📞 Contact Belota at +84 917 657 946 for expert consultation and the best conveyor solution for your production line.

Related reference: Rubber Conveyor Belts | High Quality Industrial Solutions | Belota