A flexible roller conveyor is a versatile material handling solution designed to solve space constraints in warehouses, distribution centers, and production lines. With adjustable length and configurable layouts, flexible roller conveyors offer an optimal solution for businesses operating in limited working spaces.

What Is a Flexible Roller Conveyor? – Structure & Classification

A flexible roller conveyor is a modular conveyor system capable of expanding and contracting in length, operating in straight lines or curving around corners as required. After use, the system can be easily folded and stored, helping save valuable warehouse space.

Thanks to its convenient design, this type of conveyor is especially useful in logistics operations, factories, and loading/unloading goods onto trucks or containers, helping optimize material flow and reduce manual labor.

Structure

The conveyor features a modular structure that allows easy assembly, disassembly, and relocation. Rollers are connected by flexible joints, enabling the conveyor to expand or fold compactly when not in use. The frame is equipped with mobile caster wheels, making it easy to position the conveyor within various production or handling areas.

Classification

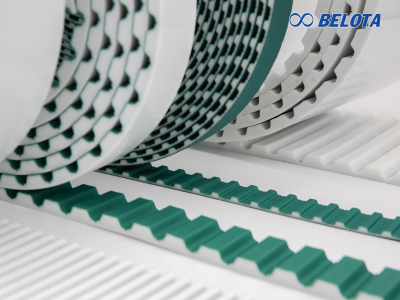

Flexible roller conveyors are classified based on their operating mechanism and roller material to meet different usage requirements.

By Operating Mechanism:

-

Gravity flexible roller conveyor: Goods move by manual pushing or natural gravity. This type has a simple structure, lower investment cost, and is suitable for light to medium-duty material transfer.

-

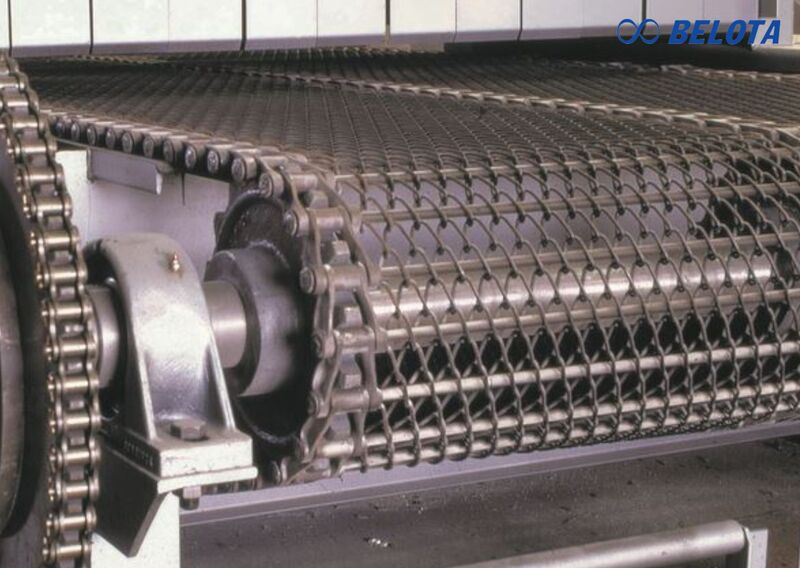

Powered flexible roller conveyor: Uses a motor and drive system to move goods automatically, reducing manual effort and suitable for high-frequency operations.

Ứng dụng của băng tải con lăn xếp

By Roller Material:

-

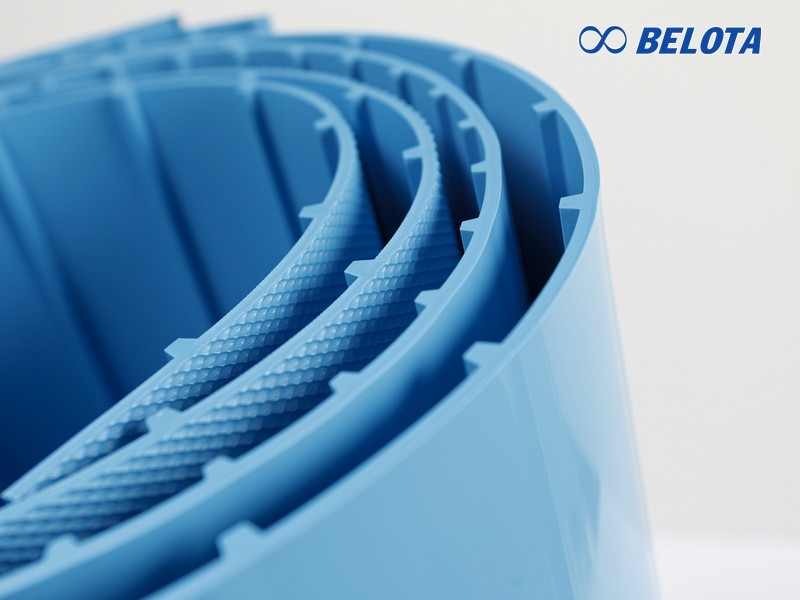

Plastic rollers: Lightweight, low noise, ideal for cartons and packaged goods.

-

Steel or galvanized rollers: Higher load capacity, suitable for heavier packages and harsher working environments.

Expansion Range & Technical Specifications

-

Expansion ratio: Approximately 50% of the extended length. For example, when fully extended to 2 m, the conveyor can be retracted to about 1 m, saving storage space and improving mobility.

-

Frame material: Galvanized steel, stainless steel, or powder-coated steel

-

Roller diameter: 50 mm – 150 mm

-

Working length: 2 m – 12 m

-

Conveyor width: 500 mm – 1,000 mm

-

Drive system: Chain drive, electric motor

-

Load capacity: Up to 100 kg

-

Length adjustment range: 2 m – 12 m

-

Functionality: Mobile, foldable for compact storage

Key Features of Flexible Roller Conveyors

-

High flexibility: Can be extended, retracted, or curved at various angles (from 30° to 180°), and also operate in straight-line configurations when required.

-

Space-saving design: Easily folded and stored when not in use, optimizing warehouse space.

-

Easy mobility: Equipped with lockable caster wheels for quick relocation to different work areas.

-

Multiple operating options: Can operate manually or be integrated with a motorized drive system to improve efficiency.

-

Practical applications: Ideal for loading/unloading, packing, and transporting goods in warehouses and dispatch areas, especially where space is limited.

-

Product requirements: Best suited for goods with flat, rigid bottoms such as cartons, milk boxes, confectionery packages, etc., ensuring stable and efficient transport.

>> See Also: Steel Roller Conveyors – High Quality, Competitive Price | Belota

Disadvantages of Flexible Roller Conveyors

Flexible roller conveyors have limited load capacity and are mainly suitable for light to medium-weight goods. They are not recommended for heavy pallets or large industrial materials. Due to their expandable design, stability may decrease when fully extended or when used on uneven floors.

Additionally, folding joints and rollers may wear faster during continuous operation, and this type of conveyor is less suitable for high-capacity automated production lines.

Applications of Flexible Roller Conveyors

-

Warehouses & distribution centers: Ideal for moving goods between zones or from trucks into storage areas quickly and efficiently, especially in limited spaces.

-

Production lines: Supports the transport of components and products in confined areas without interrupting production flow, improving operational efficiency.

-

Packaging & goods handling: Suitable for food, beverage, and chemical industries where packaged goods need to be transported without affecting product quality.

-

Import & export operations: Flexible and mobile design makes loading and unloading containers or trucks faster and more efficient.

How Much Does a Flexible Roller Conveyor Cost?

The investment cost of a flexible roller conveyor depends on its configuration and operating method. Current market prices generally fall into two main categories:

-

Gravity flexible roller conveyor: Starting from approximately 2,500,000 VND per meter

-

Powered flexible roller conveyor: From 9,000,000 VND per meter and above

Actual pricing may vary depending on working length, expansion range, required load capacity, frame and roller materials, and optional accessories. For optimal cost efficiency, technical consultation is recommended before purchasing.

Frequently Asked Questions (FAQ)

Can a flexible roller conveyor be curved?

Yes. It can operate in straight lines or curve flexibly around corners, making it suitable for narrow or complex loading areas.

Can flexible roller conveyors handle heavy loads?

They are not recommended for heavy goods or large pallets. They are best suited for light to medium loads, typically under 100 kg.

Are flexible roller conveyors easy to move?

Yes. They are equipped with caster wheels, allowing easy repositioning within warehouses or production areas.

Can the conveyor be stored when not in use?

Yes. It can be quickly folded and stored, helping save storage space.

What is the difference between gravity and powered flexible roller conveyors?

Gravity conveyors operate manually at a lower cost, while powered conveyors use motors to automate material handling and reduce labor.

Trusted Supplier of Flexible Roller Conveyors

Flexible operation, easy mobility, and space optimization – Belota flexible roller conveyors are the ideal solution for loading/unloading areas, warehouses, and modern logistics centers. We are committed to delivering:

✅ Robust construction & stable operation – Durable metal frames and high-quality rollers

✅ Flexible expansion – Easy length adjustment to suit operational needs

✅ Convenient mobility – Equipped with wheels for quick repositioning

✅ Space-saving design – Foldable when not in use

✅ Custom configurations – Flexible options for length, width, roller type, and load capacity

✅ Efficient material transfer – Ideal for cartons and light to medium packages

✅ Professional consultation – Tailored solutions for warehouses, docks, and containers

✅ Fast installation & easy maintenance – Minimized downtime

✅ Custom fabrication – Easy integration with other conveyor systems

Contact us now at 0917 657 946 for expert consultation and the best conveyor solution for your operation.

>> Learn more: Roller Conveyors | Durable Material Handling Systems