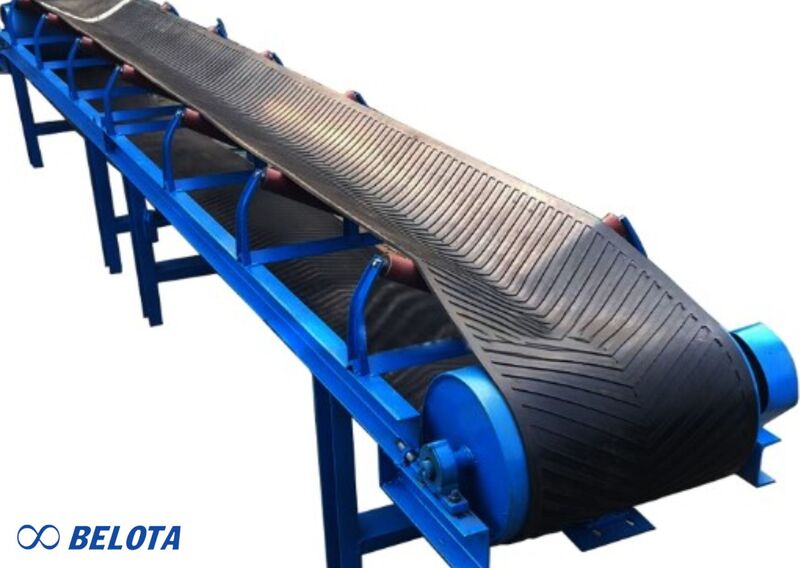

Rubber trough conveyor belts are an optimal solution for bulk material handling in mining, construction, and heavy industries thanks to their high load capacity, excellent spillage prevention, and durable performance in harsh environments. Featuring a rubber belt formed into a V-shaped or U-shaped trough combined with trough idlers, this system significantly increases conveying capacity, minimizes material loss, and optimizes operating costs. If you are looking for an efficient conveyor system for transporting construction materials or heavy agricultural products, explore this article with Belota.

What Is a Rubber Trough Conveyor Belt?

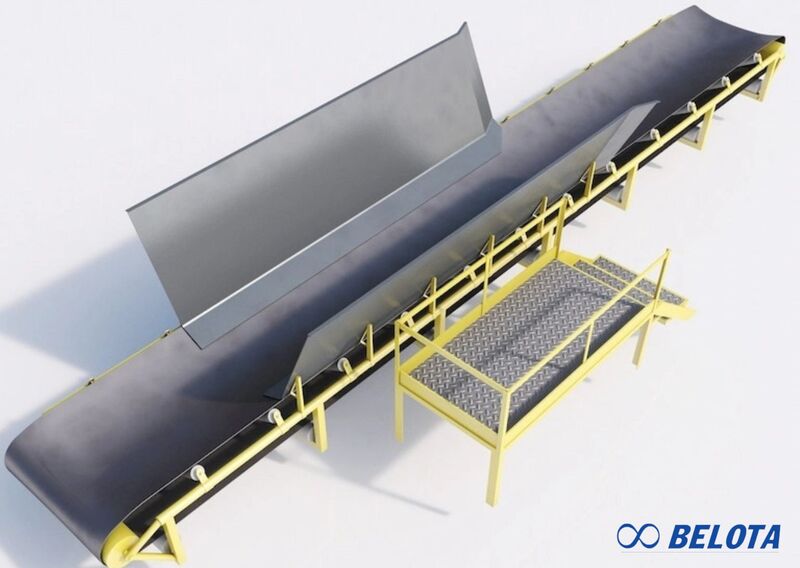

A rubber trough conveyor belt is a specialized conveying system designed for transporting large volumes of bulk materials. The rubber belt is formed into a trough shape (V or U) by angled idler rollers, allowing materials to remain centered and stable during transport. With its exceptional load-bearing capacity, abrasion resistance, and spillage control, this type of conveyor is a key solution for industries such as mining (coal, ore), construction materials (sand, stone), and agriculture.

Structure and Working Principle

Key Components

A Belota rubber trough conveyor system consists of the following core components:

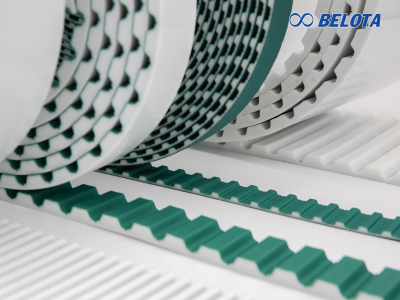

- Rubber conveyor belt: The main load-bearing element, available in smooth rubber (for horizontal conveying) or V-cleated rubber (for inclined applications).

- Heavy-duty conveyor frame: Manufactured from powder-coated structural steel or stainless steel, ensuring rigidity and vibration-free operation under full load.

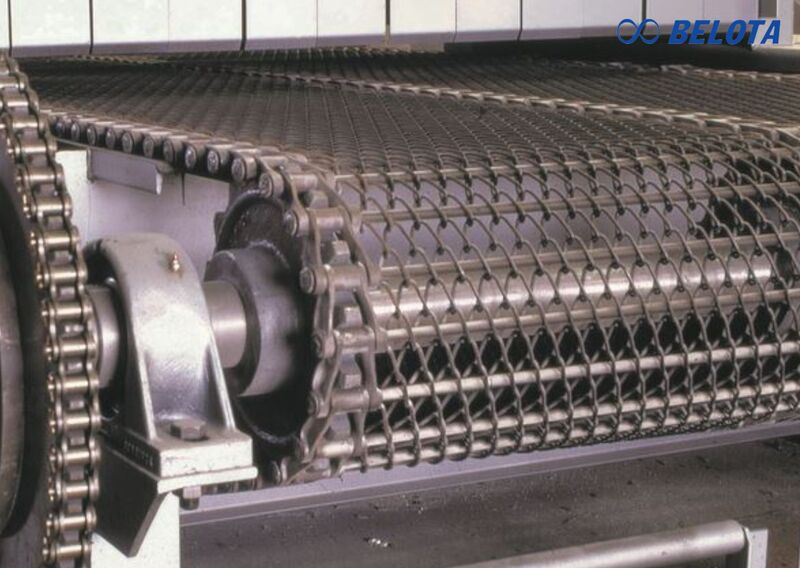

- Trough idler sets: Typically 3-idler configurations forming a V or trough shape to prevent material spillage.

- Drive & tail pulleys: Made from galvanized steel or stainless steel to ensure optimal traction and smooth belt movement.

- Adjustable height mechanism: Allows easy adjustment of the discharge height to match trucks, containers, or stockpiles.

- Mobile wheels: Heavy-duty rubber-coated wheels enable easy relocation within yards or job sites.

- Return idlers: Straight rollers supporting the return side of the belt, preventing belt sagging.

- Electrical control system: Smart control panel for operation, emergency stop, and motor protection.

- Flexible power options: Available with single-phase (220V) or three-phase (380V) motors for light to heavy industrial use.

>> See Also: V-Type Chevron Rubber Conveyor Belts | High Grip & Heavy Duty

Working Principle

When the motor operates, the drive pulley rotates and generates friction to move the belt along the trough idlers. Bulk material fed into the loading hopper is securely held within the trough and conveyed smoothly to the discharge point without shifting or spilling.

Key Advantages of Rubber Trough Conveyor Belts

Using a rubber trough conveyor offers outstanding benefits for bulk material handling:

- Extremely high conveying capacity: The deep trough design increases material volume, allowing hundreds to thousands of tons per hour.

- Excellent spillage prevention: The trough profile keeps materials centered, even with granular, powdered, or large-sized materials.

- Adaptable to complex terrain: Suitable for flat layouts, steep inclines, and long-distance routes across challenging environments.

- High durability and stability: Abrasion-resistant rubber belts and reinforced steel frames ensure reliable operation in harsh conditions such as mines and ports.

- Optimized operating costs: Reduces material loss, labor costs, and maintenance expenses.

Reference Technical Specifications

- System dimensions: Flexibly designed based on material characteristics and specific customer requirements.

- Drive motor: Standard industrial motor, with optional integration of sensors and a variable frequency drive (VFD) for speed control.

- Conveyor belt: Smooth rubber belt with common thicknesses ranging from 5 mm to 12 mm, suitable for heavy-duty bulk material handling.

- Frame structure: Fabricated from powder-coated steel or stainless steel, ensuring high rigidity and corrosion resistance.

- Drive shaft / pulley shaft: Manufactured from steel or stainless steel to provide durability and stable power transmission.

Common Types of Rubber Trough Conveyor Belts

Horizontal Trough Conveyor

The most common type used in factories and storage yards.

- Structure: 3-idler trough sets forming a V or U shape.

- Belt surface: Typically smooth rubber belts.

Inclined Trough Conveyor

Used for transporting materials between different height levels.

Feature: V-cleated rubber belts prevent material rollback and improve traction on steep inclines.

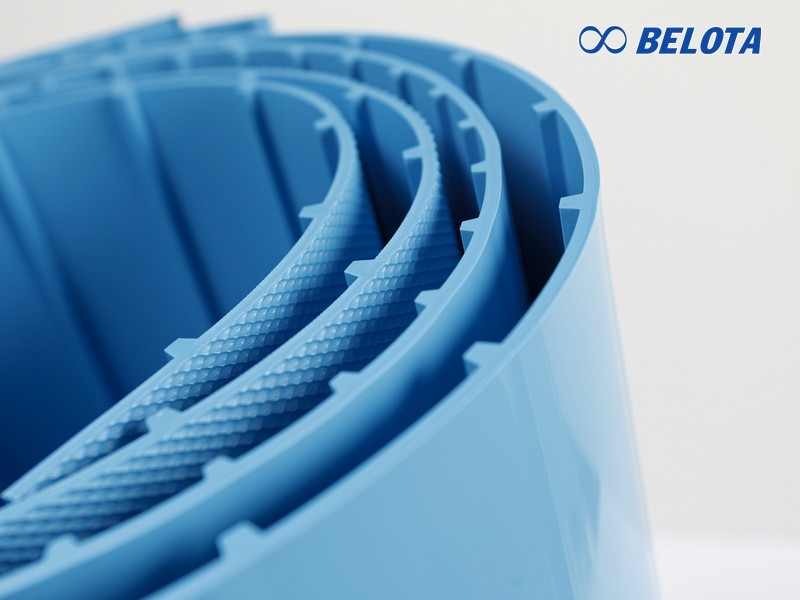

Sidewall (Corrugated) Trough Conveyor

A specialized solution for limited spaces or extremely steep angles.

- Structure: Corrugated sidewalls with internal cleats forming enclosed compartments.

- Advantage: Enables high-angle conveying without spillage.

Design and Installation Considerations

To ensure long-term performance and cost efficiency, accurate technical calculations are essential:

- Conveyor belt thickness: Typically 5mm–20mm, selected based on EP fabric layers and load requirements.

- Pulley diameter: Must be proportional to belt thickness to prevent internal fabric fatigue.

- Trough idler configuration:

- 2-idler sets for belt widths under 600mm

- 3-idler sets for belt widths ≥ 650mm to achieve optimal trough depth

- Additional accessories: Sidewalls, scrapers, or guide rollers to improve belt tracking and inclined conveying efficiency.

- Frame structure: Galvanized or anti-corrosion coated steel recommended for outdoor, mining, or quarry environments.

Typical Applications

Thanks to its high capacity and anti-spillage design, rubber trough conveyors are widely used in:

- Mining & Construction: Coal, ore, sand, gravel, and rock transportation.

- Material Processing: Conveying clinker, cement, limestone, and raw powders in batching plants.

- Agriculture & Processing: Grain, feed, sugar, and bulk agricultural products.

- Heavy Industry: Fertilizers, wood chips, chemicals, and other bulk raw materials.

>> See Also: Bucket Conveyors for Bulk Materials | Durable & High Capacity

Reliable Supplier of Rubber Trough Conveyor Belts

High capacity – Minimal spillage – Long-term durability - Belota rubber trough conveyor belts are the preferred choice for modern industrial facilities. We are committed to delivering:

- Extremely high load capacity – Multi-ply EP rubber belts with superior abrasion resistance

- Effective spillage control – V/U-shaped trough idlers ensure stable material flow

- Durable operation – Reliable performance in harsh industrial environments

- Custom-built solutions – Tailored belt width, length, trough depth, and motor power

- Robust frame construction – Heavy-duty steel with anti-corrosion coating

- Adaptable to difficult terrain – Suitable for long distances and steep inclines

- Accurate technical consulting – Correct belt and idler selection for each application

- Fast installation & easy maintenance – Nationwide technical support

- Long-term investment efficiency – Extended service life and reduced operating costs

📞 Contact Belota today: +84 917 657 946 for expert consultation and the most suitable conveyor solution for your production line.

>> See more: Rubber Conveyor Belts | High Quality Industrial Solutions | Belota