Rubber bucket conveyor belts are widely chosen by manufacturers for production lines thanks to their ability to transport large volumes of materials quickly, safely, and continuously. In this article, Belota provides a comprehensive overview of the features, applications, and key benefits of rubber bucket conveyors in industrial operations.

What Is a Rubber Bucket Conveyor Belt?

A rubber bucket conveyor belt (also known as a bucket elevator) is a mechanical conveying system used to transport bulk materials in granular or powder form from one location to another, typically in a vertical or inclined direction. With outstanding durability and high conveying capacity, this system is widely used in industries such as construction, chemicals, food processing, and heavy manufacturing, where continuous and reliable material handling is required.

>> Related article: Rubber Trough Conveyor Belts – Heavy Duty | Belota

Basic Structure of a Rubber Bucket Conveyor

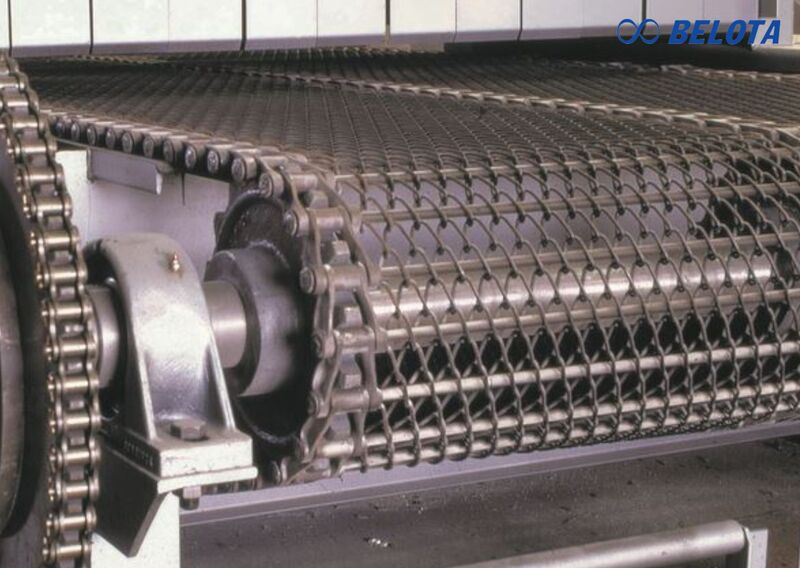

A rubber bucket conveyor consists of multiple critical components that work together to ensure efficient and stable operation:

| Component | Description |

|---|---|

| Drive pulley | The main driving component, typically manufactured from standard-grade steel. |

| Tail pulley | Installed with the bucket belt to maintain proper belt tension and friction between the pulley and belt. |

| Conveyor casing/frame | Fabricated from reinforced steel with stiffeners to ensure rigidity. The outer casing is covered with steel sheets to prevent dust leakage and material spillage. |

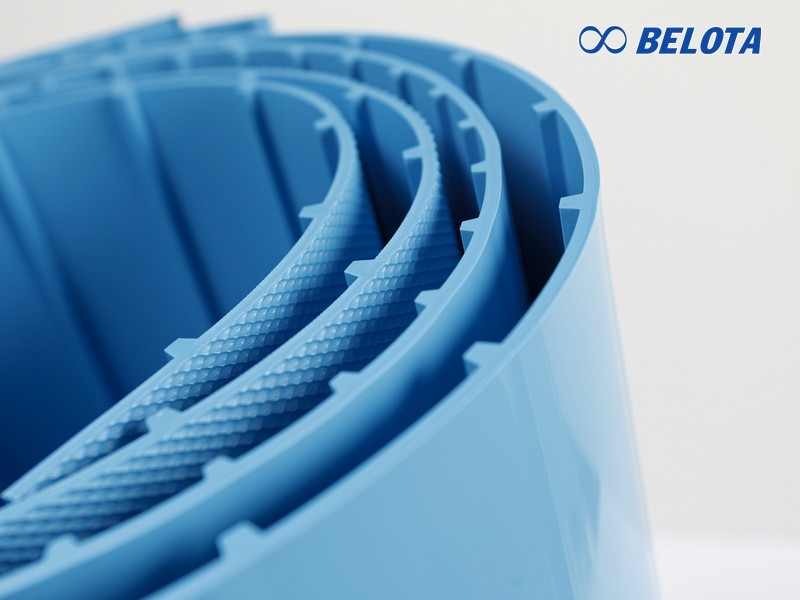

| Bucket belt | Made from synthetic rubber reinforced with internal fabric plies for strength and flexibility. |

| Bucket bolts | Manufactured from galvanized steel or cast steel, heat-treated to improve hardness, wear resistance, and toughness. |

| Buckets | Made from steel, plastic, or stainless steel depending on the application. |

| Bucket elevator assembly | Includes the elevator casing, boot section, and head section. The drive pulley is mounted at the head, while the tail pulley is installed at the boot. Buckets are fixed to the belt using bucket bolts. |

| Additional components | Discharge chute, inlet chute, support platform, electrical control panel, speed switch, monitoring devices, and belt misalignment switch. |

Working Principle of Rubber Bucket Conveyors

Rubber bucket conveyors operate based on a combination of mechanical motion and gravity to continuously lift materials from a lower point to a higher elevation:

- Material loading: Bulk material is fed into the buckets through the inlet chute.

- Vertical or inclined lifting: Buckets move upward along the conveyor path, carrying material securely.

- Material discharge: When the buckets reach the head section, material is discharged through the outlet chute into the receiving area.

Technical Specifications of Rubber Bucket Conveyor Belts

- Belt width: 150 – 2000 mm (common sizes: 300, 400, 500, 650, 800, 1000 mm)

- Total belt thickness: 6 – 20 mm

- Number of fabric plies: 2 – 6 plies (EP100, EP150, EP200, EP250)

- Fabric tensile strength: 100 – 350 N/mm

- Top rubber cover thickness: 2 – 6 mm

- Bottom rubber cover thickness: 1.5 – 4 mm

- Rubber cover types: Abrasion-resistant, heat-resistant, oil-resistant

- Belt tensile strength: 160 – 1000 N/mm

- Heat resistance: Standard -20°C to +80°C

- Heat-resistant: up to 120°C

- High-temperature types: 150–180°C

- Bucket fixing pitch: 100 – 500 mm (depending on bucket type)

- Operating speed: 0.8 – 3.5 m/s

- Belt splicing method: Hot vulcanized splice or mechanical fastening

- Rubber hardness: 60 ± 5 Shore A

- Abrasion resistance: <120 mm³ (DIN 22102)

- Conveying capacity: 1 – 500 tons/hour depending on material and industry

Comparison: Rubber Bucket Conveyor vs Other Types

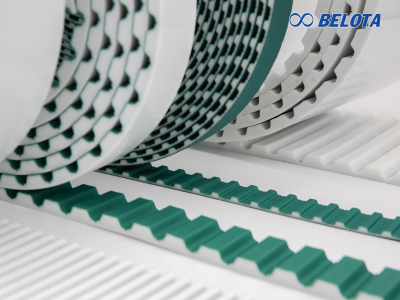

| Criteria | Rubber Bucket Conveyor | Plastic Bucket Conveyor | Chain Bucket Elevator |

|---|---|---|---|

| Main structure | Rubber belt + steel/plastic buckets | Plastic buckets + PVC/PU/rubber belt | Steel chain + steel buckets |

| Load capacity | Medium to heavy | Light to medium | Heavy to extremely heavy |

| Heat resistance | Good (70–120°C, higher for heat-resistant types) | Low (≤ 60–80°C) | Excellent (120–300°C depending on type) |

| Durability & lifespan | High | Medium | Very high |

| Abrasion resistance | Good | Fair | Excellent |

| Operational stability | Smooth, low vibration | Very smooth | Very rigid but noisier |

| Typical applications | Ore, coal, cement, bulk materials | Agriculture, food, animal feed | Clinker, stone, ore, harsh environments |

| Investment cost | Medium | Low | High |

| Key advantages | Durable, flexible, wear-resistant | Lightweight, economical | Extremely strong, long service life |

| Limitations | Not suitable for extreme loads or very high temperatures | Limited strength | Noisy, high cost, complex maintenance |

>> Related: V-Type Chevron Rubber Conveyor Belts | High Grip & Heavy Duty

Why Choose Rubber Bucket Conveyors?

Excellent Wear and Impact Resistance

The reinforced rubber belt effectively withstands abrasion and impact from sharp or heavy materials, significantly extending system lifespan.

Smooth Operation with Reduced Noise

The elastic properties of rubber absorb vibration, ensuring stable and quiet operation—ideal for continuous production environments.

Good Heat Resistance

Heat-resistant rubber belts allow safe conveying of hot materials, making them suitable for cement, coal, and metallurgical industries.

Versatile Material Handling

Capable of transporting various bulk materials including coal, sand, stone, powder, and grains. Specialized designs can handle high-temperature materials.

Increased Productivity

High conveying capacity enables fast material transfer, improving overall production efficiency and reducing labor costs.

Space-Saving Design

Vertical conveying minimizes floor space usage and allows flexible installation in confined areas.

Enhanced Safety

Rubber belts absorb impact, reduce component wear, minimize dust generation, and improve operator safety compared to chain systems.

Key Factors When Selecting a Bucket Conveyor

To ensure optimal performance and longevity, consider the following factors:

- Material characteristics: Size, shape, abrasiveness, temperature, and moisture content

- Operating environment: High temperatures, dust levels, or corrosive conditions

- Required capacity: Match conveyor capacity to production demand to avoid overloading or underutilization

Trusted Supplier of Rubber Bucket Conveyors

Stable conveying, efficient vertical lifting - Belota rubber bucket conveyors (bucket elevators) are an optimal solution for industrial bulk material handling in vertical or inclined applications. We are committed to delivering outstanding value through:

✅ Stable load capacity & durability – Multi-ply EP rubber belts with excellent wear and impact resistance

✅ High conveying efficiency – Continuous material lifting with minimal loss and downtime

✅ Custom-built design – Adjustable lifting height, capacity, bucket type, and bucket spacing

✅ Smooth and low-vibration operation – Elastic rubber belt reduces noise and mechanical wear

✅ Robust structure – Reinforced steel frame designed for heavy-duty industrial environments

✅ Heat and abrasion resistance – Suitable for cement, coal, ore, clinker, and hot bulk materials

✅ Professional technical consulting – Accurate load calculation and proper belt & bucket selection

✅ Fast installation & easy maintenance – Nationwide technical support with clear procedures

✅ Long-term investment efficiency – Extended service life and reduced operating and maintenance costs

📞 Contact Belota today: +84 917 657 946 for expert consultation and the most suitable conveyor solution for your production line.

>> See more: Rubber Conveyor Belts | High Quality Industrial Solutions | Belota