The treadmill conveyor belt is a critical component that directly determines the smoothness, safety, and overall lifespan of a treadmill. When the belt becomes worn, hardened, or misaligned, the treadmill may generate excessive noise and pose safety risks to users. Understanding the structure, technical specifications, proper selection, and replacement of treadmill belts helps ensure stable operation, long service life, and an optimal workout experience.

In this article, Belota provides a comprehensive overview of what a treadmill running belt is, its construction and technical specifications, popular belt models, how to choose the right belt for DC or AC motors, price references, and where to buy reliable treadmill conveyor belts on the market today.

What Is a Treadmill Conveyor Belt?

A treadmill conveyor belt (also known as a treadmill running belt or running deck belt) is the component that comes into direct contact with the user’s feet, creating a continuous moving surface during operation. It is one of the most important treadmill parts, directly affecting running comfort, safety, machine durability, and overall user experience.

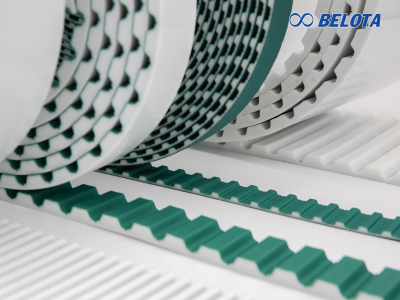

Treadmill belts belong to a specialized PVC conveyor belt category, specifically designed for continuous friction, variable speeds, and concentrated loads from running or walking. The belt surface is usually treated with anti-slip textures or patterns to enhance grip and reduce the risk of slipping during intense workouts.

Compared to standard industrial PVC conveyor belts, treadmill running belts have distinct differences:

- Higher shock absorption and quieter operation

- Superior resistance to continuous friction without premature hardening

- Low elongation, ensuring stable and straight belt tracking

- Optimized for user safety rather than material handling loads

See Also: PVC Anti-Static Conveyor Belt | ESD Standard | Belota

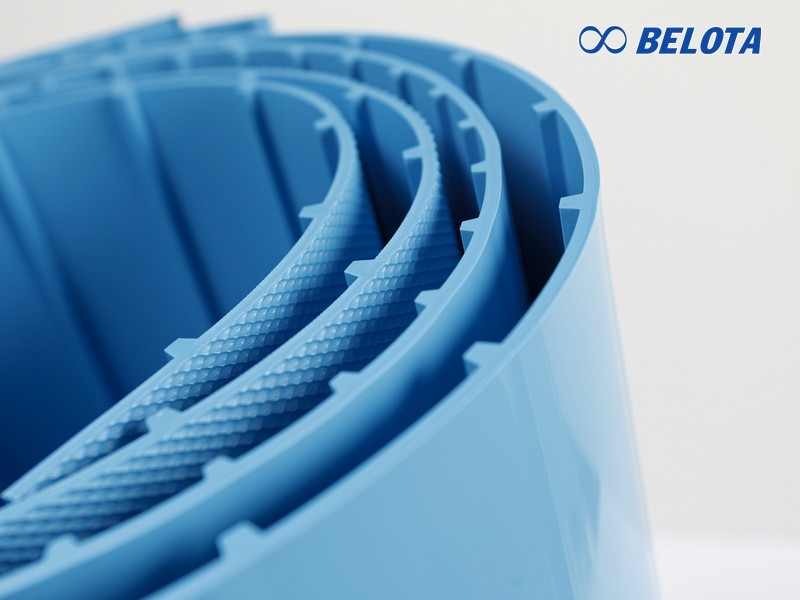

Structure of PVC Treadmill Conveyor Belts

PVC treadmill conveyor belts are engineered with a multi-layer construction to ensure smooth operation, continuous friction resistance, and user safety. Each layer serves a specific function to enhance durability and performance.

- Top running surface layer: This layer directly contacts the user’s feet and determines safety and comfort. Anti-slip textures or patterns improve traction and reduce slipping when walking or running at high speeds.

- Reinforcement layer (belt core): The core layer bears body weight and repeated impact forces. It is typically made of high-strength synthetic fibers or reinforced technical fabric to minimize elongation and maintain belt stability.

- Shock-absorbing layer: Some premium treadmill belts include an additional cushioning layer to absorb impact, reduce stress on knees and ankles, and minimize vibration and noise during use.

- Bottom friction layer: The bottom layer contacts the running deck and rollers, providing controlled friction to ensure proper grip and prevent belt slippage during acceleration.

Basic Technical Specifications

Treadmill conveyor belts are designed to withstand continuous friction, human body weight, and smooth operation. Common specifications include:

- Material: PVC, PU, or synthetic rubber for durability, abrasion resistance, and grip

- Standard thickness: 1.6 – 3.0 mm, suitable for home and commercial treadmills

- Construction: 2 – 4 layers (running surface, reinforcement, cushioning, bottom layer)

- Surface texture: Smooth matte, golf pattern, or diamond pattern

- Load capacity: High tensile strength, low elongation, stable long-term operation

- Dimensions: Custom-manufactured according to each treadmill model

Best-Selling Treadmill Conveyor Belt Models

Belota supplies a wide range of specialized treadmill conveyor belts, suitable for replacement, maintenance, and upgrades for most treadmill models on the market. These belts are compatible with both DC motor home treadmills and AC motor commercial gym treadmills.

Belota treadmill belts are widely used for popular brands such as ELIP, KINGSPORT, MOFIT, KONLEGA, SPORT 1, TECHNOGYM, NORDICTRACK, JOHNSON, MATRIX, EBETE, EVERE, ROYAL, ensuring smooth, quiet, and durable performance.

| Model | Surface | Thickness | Ply | Min. Pulley Diameter (mm) | Operating Temperature (°C) | Effective Tensile Force at 1% Elongation (N/mm) | Suitable Applications |

|---|---|---|---|---|---|---|---|

| DT-S14/31 | Fine Sandblast | 1.4 mm | 1 | 30 | -15 ~ 80 | 5 | Home treadmill, light-duty use |

| DT-S15/7R | Golf Pattern | 1.5 mm | 1 | 30 | -15 ~ 80 | 5 | Home treadmill, DC motor |

| DT-S18/7R | Golf Pattern | 1.8 mm | 2 | 40 | -15 ~ 80 | 7 | Premium home treadmill |

| DT-S20/7R | Golf Pattern | 2.0 mm | 2 | 40 | -15 ~ 80 | 8 | Small gym treadmill |

| DT-S23/7R | Golf Pattern | 2.3 mm | 2 | 50 | -15 ~ 80 | 12 | Commercial treadmill, high load |

| DT-S25/7R | Golf Pattern | 2.5 mm | 2 | 40 | -15 ~ 80 | 12 | High-intensity gym treadmill |

| DT-S14/1R | Diamond Pattern | 1.4 mm | 1 | 20 | -15 ~ 80 | 8 | Home treadmill, high grip requirement |

| DT-S18/1R | Diamond Pattern | 1.8 mm | 2 | 40 | -15 ~ 80 | 8 | DC & AC motor treadmills |

| DT-S20/1R | Diamond Pattern | 2.0 mm | 2 | 40 | -15 ~ 80 | 12 | Gym treadmill, continuous operation |

| DT-S23/1R | Diamond Pattern | 2.3 mm | 2 | 50 | -15 ~ 80 | 12 | Commercial treadmill, heavy-duty use |

How to Choose the Right Treadmill Conveyor Belt

To ensure smooth, durable operation without affecting the motor, selecting the correct belt based on treadmill size and motor type is essential.

Selection by Belt Dimensions

Each treadmill has different belt widths and circumferences. The belt must be precisely manufactured to ensure proper tension and stable tracking. Wider and longer belts usually require stronger construction, and diagonal splicing must be done accurately to prevent vibration or misalignment.

Selection by Motor Type

DC Motor Treadmills

- Recommended belt thickness: around 1.6 mm

- Ensures quiet operation and reduced motor load

- Avoid overly thick belts, which may cause increased friction, noise, motor strain, and deck damage

AC Motor Treadmills

- Can use thicker belts, typically 2.5 mm or more

- Suitable for powerful motors with large rollers

- Ideal for commercial gyms and high-intensity usage

Selection by Usage Purpose

- Home use: thinner, quieter belts with energy efficiency

- Gym/commercial use: thicker belts with high wear resistance and load capacity

Price Range of PVC Treadmill Conveyor Belts

Treadmill belt prices vary depending on size, material, thickness, construction, and included services.

Standard PVC treadmill belts, custom-cut to size, typically range from 700,000 – 1,000,000 VND per m², suitable for home or medium-duty machines.

For common treadmill sizes (belt width approx. 48–58 cm, circumference 2,800 – 3,400 mm), many suppliers offer complete packages including belt, splicing, and installation, priced around 1,800,000 – 2,800,000 VND, depending on belt quality and thickness.

Premium treadmill belts made from PU or synthetic rubber with multi-layer construction and high abrasion resistance are priced higher, especially for commercial and gym treadmills operating continuously.

Where to Buy Reliable Treadmill Conveyor Belts?

With stable motion, durable performance, and international safety standards, Belota treadmill conveyor belts are a trusted choice for modern fitness equipment. We are committed to providing:

- Genuine, durable materials for stable long-term operation

- Quiet running performance with optimized friction control

- Precision manufacturing tailored to each treadmill model

- Anti-slip surfaces for enhanced user safety

- Compatibility with most home and commercial treadmill brands

- Expert technical consultation based on DC or AC motor requirements

- Fast replacement and installation services with thorough testing

- Custom cutting and splicing for easy maintenance and replacement

Contact Belota at 0917 657 946 to receive professional advice and the most suitable treadmill belt solution for your equipment.

See Also: PVC Conveyor Belts Manufacturer & Supplier | BELOTA