The mobile rubber incline conveyor is a versatile material handling solution designed to transport goods between different height levels. With an adjustable incline angle and a wheeled structure for easy relocation, this system is widely used in warehouses, ports, logistics centers, and manufacturing plants to optimize loading and unloading operations.

What Is a Rubber Incline Conveyor?

A rubber incline conveyor is a specialized conveying system that allows flexible adjustment of elevation and inclination angle, enabling automatic upward and downward material handling. This type of conveyor significantly improves loading efficiency, reduces manual labor, saves time, and ensures safe transportation of bagged goods, cartons, or pallets in industrial environments.

>> See Also: Rubber Trough Conveyor Belts – Heavy Duty | Belota

Structure of a Rubber Incline Conveyor

Although similar to conventional belt conveyors, rubber incline conveyors are enhanced with lifting mechanisms and high mobility features. Key components include:

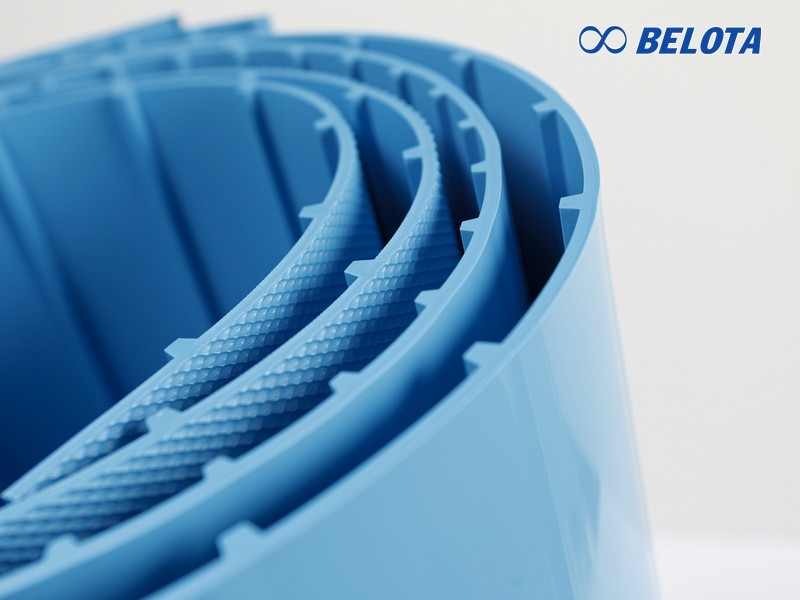

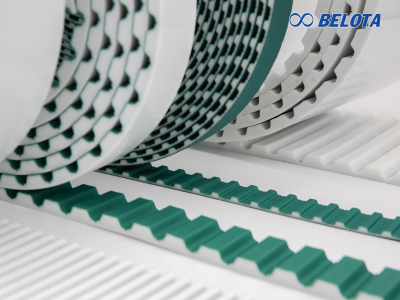

Rubber Conveyor Belt

- Properties: Made from high-tensile rubber with excellent abrasion and impact resistance.

- Design: Incline models often use V-cleated or patterned belts to increase friction, preventing material rollback on steep angles.

Heavy-Duty Conveyor Frame

- Material: Fabricated from structural steel (U-beam, I-beam) or stainless steel for high load capacity and stability.

- Structure: Truss-style design reduces overall weight while maintaining rigidity. Heavy-duty wheels are integrated underneath for easy movement within facilities.

Flexible Lifting System

This is the core feature that differentiates incline conveyors:

- Mechanism: Hydraulic cylinders or mechanical systems (screw jack, winch cable) enable fast and precise angle adjustment.

- Function: Allows the discharge end to align with truck beds, containers, or elevated loading points.

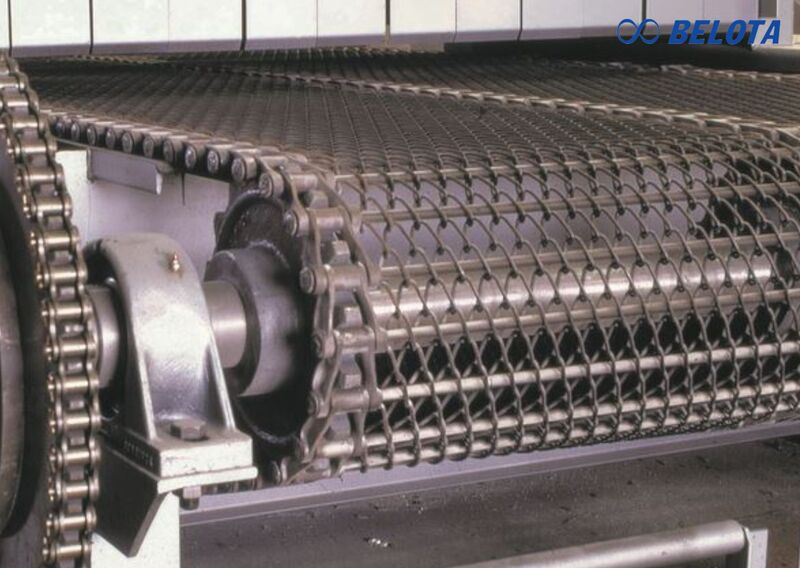

Pulley and Roller System

- Pulleys: Drive and tail pulleys ensure smooth belt traction and proper tension.

- Support Rollers: Positioned along the frame to support the belt and material load, minimizing friction and belt sag during operation.

Drive Motor System

- Motor: Gear motor selected according to designed load capacity.

- Control: Optional electrical control panel with inverter (VFD) for adjustable belt speed.

Technical Specifications of Rubber Incline Conveyor

| Item | Technical Description |

|---|---|

| Belt material | Industrial rubber, PVC, or PU (customizable) |

| Belt width | 400 – 1200 mm |

| Operating speed | Adjustable from 0.1 to 1.5 m/s |

| Frame structure | Anti-corrosion painted steel or stainless steel |

| Lifting mechanism | Mechanical, hydraulic, or electric system |

| Lifting height | 1 – 5 meters |

| Load capacity | 100 – 1000 kg |

Key Technical Advantages

Using a mobile rubber incline conveyor delivers direct efficiency improvements in logistics and production systems:

- Optimized loading & unloading: Fast transfer of goods between ground level and trucks or containers.

- Labor & cost savings: Replaces manual handling, reducing labor demand by up to 70%.

- High mobility: Easy relocation with heavy-duty wheels; precise height adjustment via hydraulic or electric lifting systems.

- Safe operation & anti-slip performance: High-friction rubber belts (especially V-cleated types) prevent slipping and material spillage on steep inclines.

- Increased productivity: Automated material flow accelerates throughput and overall operational efficiency.

- Easy integration: Modular design allows seamless connection with existing conveyor lines without major infrastructure changes.

Cấu tạo băng tải cao su nâng hạ

>> See Also: Heat-Resistant Rubber Conveyor Belts | Belota

Common Types of Rubber Incline Conveyors

Single Incline Mobile Conveyor

The most popular and cost-effective option.

- Structure: One end fixed or near ground level, the other adjustable via hydraulic or electric lifting system.

- Advantage: Compact, lightweight, and easy to position inside trucks or containers for loading.

Butterfly-Type Incline Conveyor

A specialized design featuring two independently adjustable conveyor wings.

- Structure: Dual conveyor sections connected together, capable of lifting independently or simultaneously.

- Advantage: Transfers materials between vehicles at different heights without intermediate unloading.

Dock & Port Incline Conveyor

A large-scale version designed for heavy-duty applications.

- Structure: Larger dimensions, often modular, with multiple conveyor sections layered together.

- Advantage: Extended reach, high elevation capability, and excellent performance in harsh port and marine environments.

Industrial Applications

- Logistics & Warehousing: Loading and unloading cartons, parcels, and goods from trucks and containers.

- Food & Beverage Industry: Transferring packaged products from production lines to elevated conveyors or storage areas.

- Packaging Industry: Feeding cartons or packaging materials to higher-level packing machines.

- Building Materials: Transporting heavy materials such as bricks, stones, and cement bags using cleated belts for anti-slip performance.

- Metal Processing: Handling steel billets, raw materials, or finished products between different production stages.

Trusted Supplier of Rubber Incline Conveyors

Stable elevation transport with minimal material slippage – Belota rubber incline conveyors are the optimal solution for inclined material handling in industrial environments. We deliver:

✅ Efficient lifting performance – Multi-ply EP rubber belts with high tensile strength

✅ Excellent anti-slip capability – V-cleated, chevron, or rough-top belt options

✅ Smooth & stable operation – Synchronized drive system minimizes vibration and belt misalignment

✅ Custom engineering solutions – Adjustable incline angle, belt length, load capacity, and speed

✅ Robust structural design – Heavy-duty painted or galvanized steel frames

✅ Wide material compatibility – Coal, sand, stone, cement, ore, agricultural products, fertilizers

✅ Professional technical consulting – Accurate calculation of incline angle, pulling force, belt type, and motor power

✅ Fast installation & easy maintenance – Simple structure, convenient inspection and part replacement

✅ Long-term investment efficiency – Extended service life, reduced labor and material loss

📞 Contact Belota at +84 917 657 946 for the most suitable rubber incline conveyor solution for your production line.

>> See more: Rubber Conveyor Belts | High Quality Industrial Solutions | Belota