In the sugar manufacturing industry, where product quality, hygiene, and safety are top priorities choosing the right material handling system is essential. White rubber conveyor belts for the sugar industry are an optimal solution, helping sugar producers improve operational efficiency, maintain cleanliness, and ensure superior product quality throughout the production process.

What Is an FDA White Rubber Conveyor Belt for the Sugar Industry?

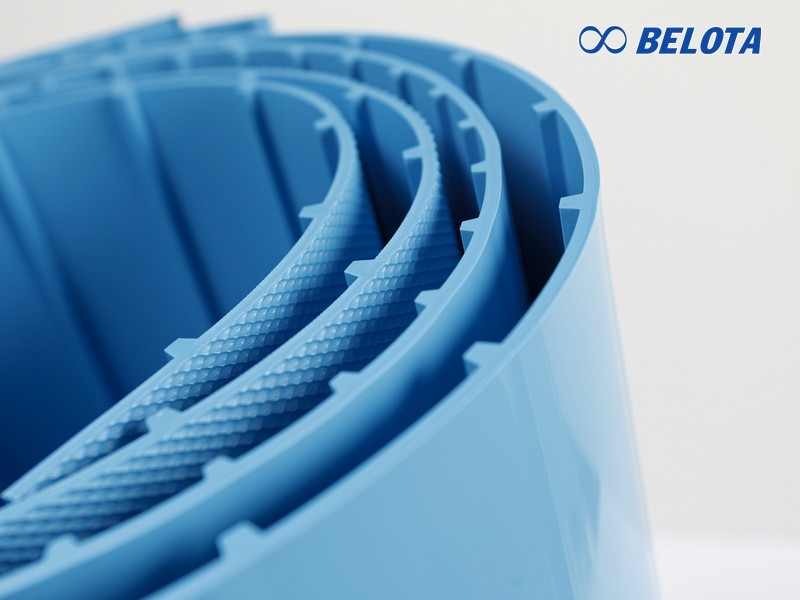

A white rubber conveyor belt for the sugar industry is a specialized rubber belt designed to transport powdered, granular materials or packaged products such as sugar, sugarcane, syrup, and related ingredients. Made from food-grade white rubber, the belt is odorless, non-toxic, and easy to clean, fully meeting strict hygiene and food safety standards in sugar and food processing applications.

A key advantage is that the belt edges are often fully molded and sealed according to custom specifications, preventing fraying, extending service life, and minimizing the risk of contamination during operation.

>> See Also: V-Type Chevron Rubber Conveyor Belts | High Grip & Heavy Duty

Structure of White Rubber Conveyor Belts for Sugar Processing

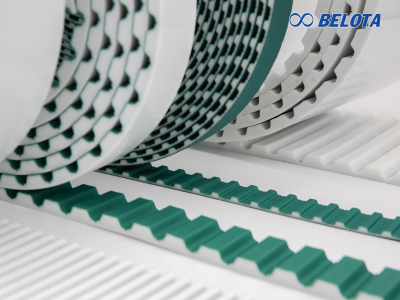

White rubber conveyor belts used in the sugar industry typically feature a smooth surface for easy cleaning and reduced material adhesion. The standard structure includes:

-

Top rubber cover: White, food-grade rubber with excellent anti-adhesion and abrasion resistance

-

EP/NN fabric plies: Enhance tensile strength and limit belt elongation

-

Bonding rubber layer: Securely holds fabric plies together

-

Bottom rubber cover: Protects the belt when in contact with rollers and reduces friction

Reference Technical Specifications

-

Belt width: 300 – 1600 mm (customizable)

-

Total thickness: 5 – 15 mm

-

Number of plies: 2 – 4 plies (EP100 – EP300)

-

Tensile strength: 200 – 1200 kN/m

-

Top cover thickness: 3 – 6 mm

-

Bottom cover thickness: 1.5 – 3 mm

-

Operating temperature: -10°C to +80°C (up to 120°C for special grades)

-

Rubber hardness: 60 ±5 Shore A

-

Abrasion resistance: <150 mm³ (DIN 22102 – Grade W)

Key Advantages of White Rubber Conveyor Belts for the Sugar Industry

As a food-grade conveyor solution specifically designed for sugar production, this belt offers several outstanding benefits:

-

Pure white appearance: Enhances hygiene control and visual inspection

-

Food-grade rubber material: Free from harmful substances, safe for direct contact with food products

-

Anti-stick surface: Reduces sugar build-up and improves cleanliness

-

High elasticity and durability: Excellent load resistance with minimal elongation

-

Moisture and water resistance: Ideal for humid production environments

-

Good heat resistance: Maintains performance under elevated operating temperatures without deformation

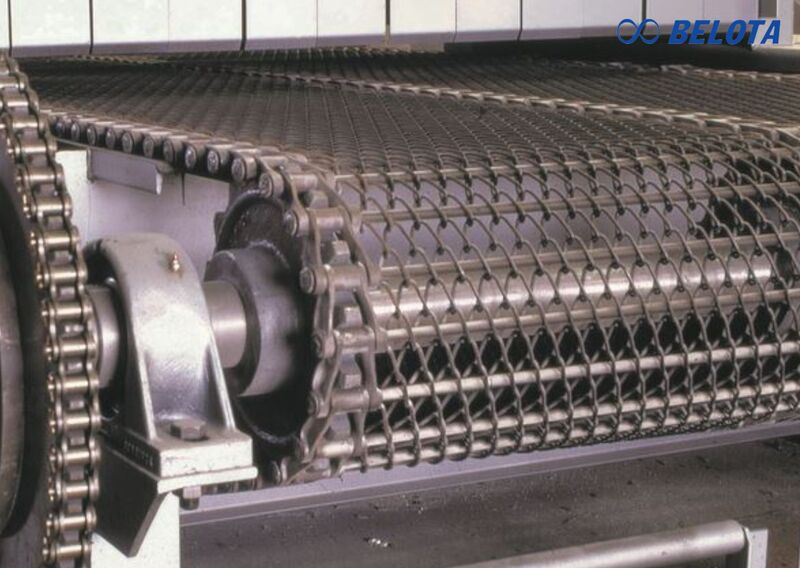

Applications in the Sugar Industry

-

Conveying raw sugar and refined sugar in production lines

-

Transporting finished products during packaging and handling stages

-

Suitable for high-humidity environments requiring strict hygiene control

-

Widely used in sugar factories and food processing plants with stringent sanitation requirements

Model băng tải cao su trắng tiêu biểu – Ammeraal Beltech (Châu Âu)

>> See Also: White PU conveyor belts - Efficient solutions from Belota

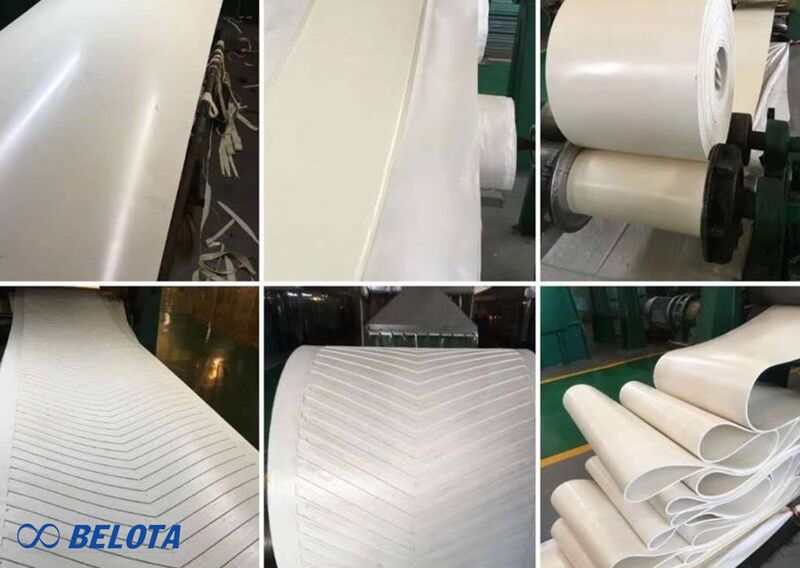

Typical White Rubber Conveyor Belt Models – Ammeraal Beltech (Europe)

Below are some popular Ammeraal Beltech white rubber conveyor belt models used in the sugar industry:

-

579259 – Flexam EF 16/2 10+20

-

576279 – Flexam EF 24/3 10+20

-

576299 – Flexam EF 50/3 13+30

-

576180 – Flexam EF 30/3 10+20

White rubber conveyor belts for the sugar industry are an ideal solution for food manufacturers especially sugar producers thanks to their safety, durability, and excellent anti-adhesion properties.

BELOTA Solutions – A Trusted Conveyor Belt Partner for the Sugar Industry

BELOTA supplies high-quality European-imported white rubber conveyor belts, including:

-

Flexam EF 16/2, EF 24/3, EF 30/3, EF 50/3 series

-

Certified to ATEX – ISO 340, safe for potentially explosive environments

-

Thickness range: 5 – 11 mm, belt lengths up to 300 m

-

Features: abrasion resistance, flame resistance, anti-static (AS), non-stick surface, sealed edges

-

Capacity: 60 – 130 tons/hour

Looking to upgrade your sugar industry conveyor system? Let BELOTA provide a tailored, cost-effective solution designed specifically for your production needs.

Related article: Rubber Conveyor Belts | High Quality Industrial Solutions | Belota