In many industries - especially food processing, pharmaceuticals, and electronics—handling and conveying highly adhesive materials such as caramel, chocolate, dough, paste, or glue is a major challenge. Conventional PU conveyor belts often suffer from sticking issues, are difficult to clean, and have limitations in operating temperature.

Silicone-coated PU conveyor belts were developed to comprehensively solve these problems by combining the mechanical strength of PU with the exceptional heat resistance and non-stick properties of silicone.

What Is a Non-Stick PU Conveyor Belt?

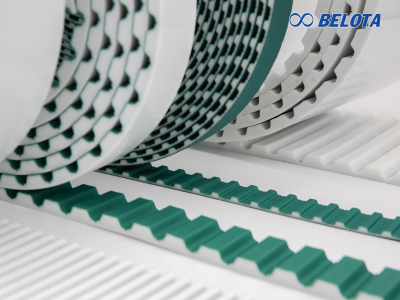

A silicone-coated PU conveyor belt is a PU belt with a silicone layer applied to its surface, creating a non-stick conveying surface. This design allows products to move smoothly without sticking or jamming while also ensuring fast and easy cleaning during maintenance and sanitation processes.

Structure

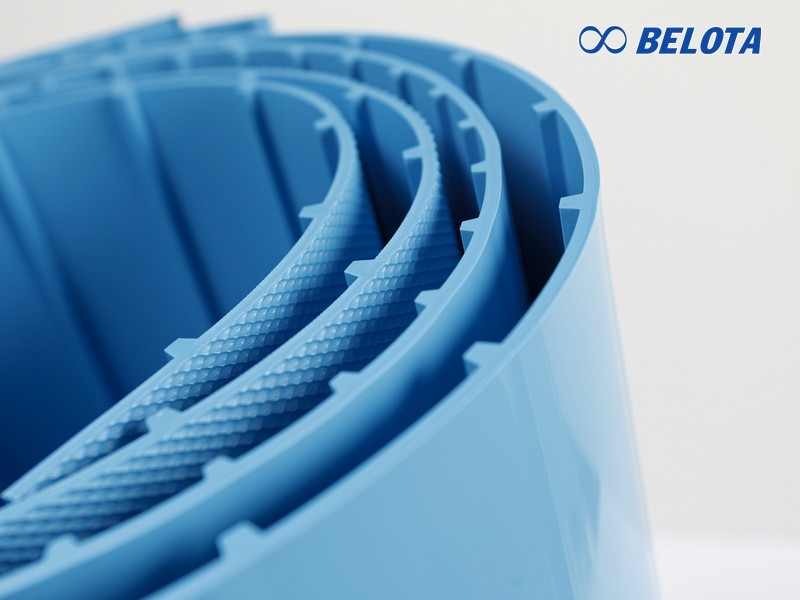

Silicone-coated PU conveyor belts are designed with a multi-layer structure, including:

- PU base layer: Provides tensile strength, elasticity, and overall belt durability

- Fabric reinforcement layer: Typically made of polyester or nylon, ensuring dimensional stability and reduced elongation

- Silicone coating layer: In direct contact with products, offering non-stick performance, high heat resistance, and oil resistance

See also: Custom PU V-Guide Conveyor Belts Solutions | Belota

Key Features

Outstanding Characteristics of Silicone-Coated PU Conveyor Belts

Excellent non-stick performance

The silicone coating creates a smooth surface that prevents products from adhering during conveying. This makes it ideal for processing lines handling high-viscosity materials or applications requiring absolute cleanliness.

Superior heat resistance

The belt operates reliably in high-temperature environments, with some models capable of withstanding instant temperatures up to 250°C. This is particularly suitable for drying, baking, and heat-pressing processes.

Strong chemical resistance

Both the silicone surface and PU core resist oils, greases, solvents, mild acids, and alkalis, allowing the belt to maintain durability in harsh industrial environments.

Easy cleaning & hygiene compliance

The smooth, low-adhesion surface prevents dust buildup and allows easy cleaning using neutral detergents. This is critical for meeting strict hygiene standards in the food and pharmaceutical industries.

High mechanical durability

PU is well known for its abrasion resistance, impact resistance, and scratch resistance. Combined with a silicone coating, the belt achieves extended service life and reduced maintenance costs.

Reference Technical Specifications

-

Total thickness: 2.0 – 5.0 mm

-

Operating temperature: -10°C to 200°C (instant up to 250°C)

-

Tensile strength (1% elongation): 150 – 250 N/m

-

Minimum pulley diameter: ≥ 80 mm

-

Hygiene standard: FDA (United States)

Practical Applications

Food Processing Industry

Conveying sticky products such as chocolate, caramel, gummy candy, pastries, and fruit jams

High-temperature processes after baking, drying, or sugar coating

Ensuring hygiene: FDA-approved silicone coating allows direct food contact and easy sanitation

Pharmaceutical Industry

Handling tablets and sensitive packaging without sticking, breakage, or deformation

High-speed packaging lines requiring stable product flow

Cleanroom environments: low dust adhesion, suitable for GMP standards

Electronics & Semiconductor Industry

Conveying electronic components such as chips, PCBs, and small devices requiring clean, non-contaminating surfaces

Anti-static (ESD) options available to protect sensitive components from electrostatic damage

Seamless integration into automated production lines and robotic handling systems

Textile Industry

Heat press machines and fabric dryers requiring high heat resistance

Fabric adhesive bonding processes where silicone prevents glue adhesion and ensures clean finished products

Chemical Industry

Handling oily materials and light solvents with excellent chemical resistance

Applications in adhesive, plastic, and rubber manufacturing to reduce material loss caused by sticking

Usage Notes

- Avoid prolonged contact with strong acids or strong alkalis to protect the silicone layer

- Clean regularly using neutral cleaning solutions; avoid harsh detergents

- Periodically check belt tension and alignment to prevent uneven wear

- For belt joining, hot pressing (thermal vulcanization) is recommended to ensure joint strength and durability

Leading Brands & Certifications

There are many silicone-coated PU conveyor belt models from reputable international manufacturers. For example, Habasit CNB-6EB-A1 is a popular Swiss-made model widely used in the food industry.

Major global brands such as Habasit (Switzerland), Forbo Siegling (Germany), and Ammeraal Beltech (Netherlands) offer silicone-coated PU belts certified with FDA, EU Food Contact, and ISO 9001, ensuring international hygiene and quality standards.

See also: PU Flat Conveyor Belts – High Quality & Durable

Reliable PU Conveyor Belt Supplier

Stable motion, durable performance – Silicone-coated non-stick PU conveyor belts from Belota are the top choice for modern factories. We are committed to delivering comprehensive conveyor solutions with the following advantages:

✅ Genuine quality & high durability – Premium materials for stable, long-term operation

✅ Optimized performance – Reduced friction and wear, helping to lower operating costs

✅ Flexible design – Customizable length, width, surface type, tensile strength, and conveying height

✅ Safety & hygiene – Suitable for food, pharmaceutical, and electronics industries

✅ Expert consultation – Tailored solutions optimized for each production line

✅ Fast installation & maintenance – Nationwide support with transparent processes

✅ Chemical & heat resistance – Reliable performance in demanding industrial environments

✅ Long-term efficiency – Extended service life and reduced life-cycle costs

✅ Custom fabrication – Easy integration with all conveyor systems

📞 Contact Belota now at +84 917 657 946 to receive professional consultation and the most suitable solution for your conveyor line.

See Also: PU Conveyor Belt | High Quality, Competitive Price | Belota