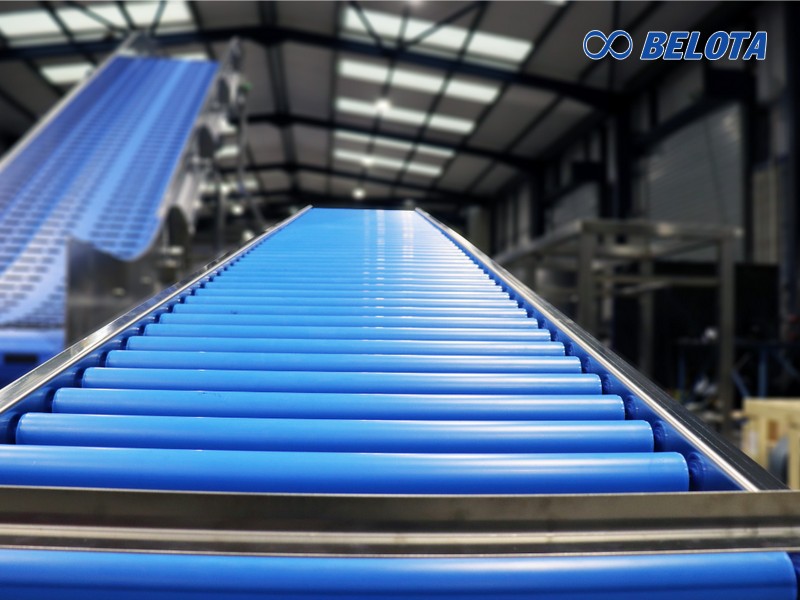

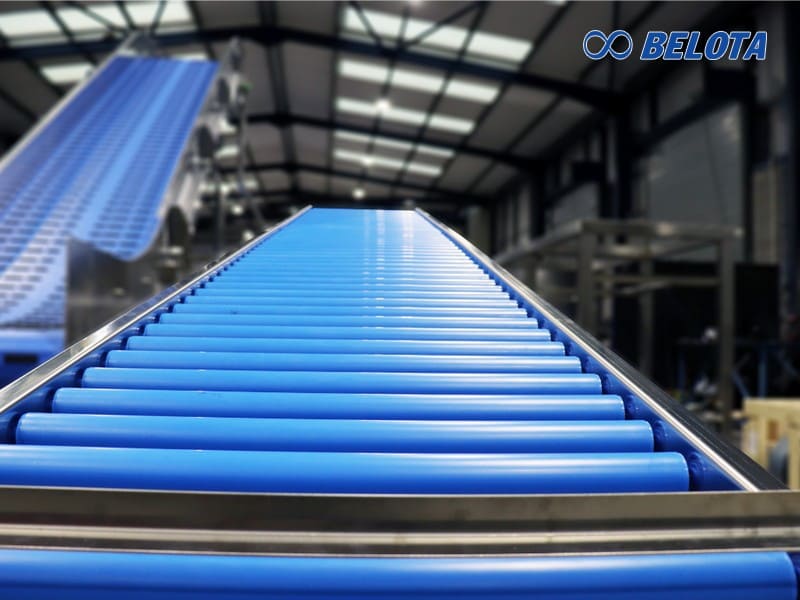

Plastic roller conveyors are among the most commonly used material handling systems today. They are widely applied across industries such as food processing, pharmaceuticals, cold storage, packaging, and logistics. Manufactured with PVC/PU plastic rollers, this conveyor system offers key advantages including lightweight construction, durability, quiet operation, and excellent corrosion resistance. In this article, Belota will provide a detailed overview of plastic roller conveyor features, advantages, applications, and pricing considerations.

What Is a Plastic Roller Conveyor?

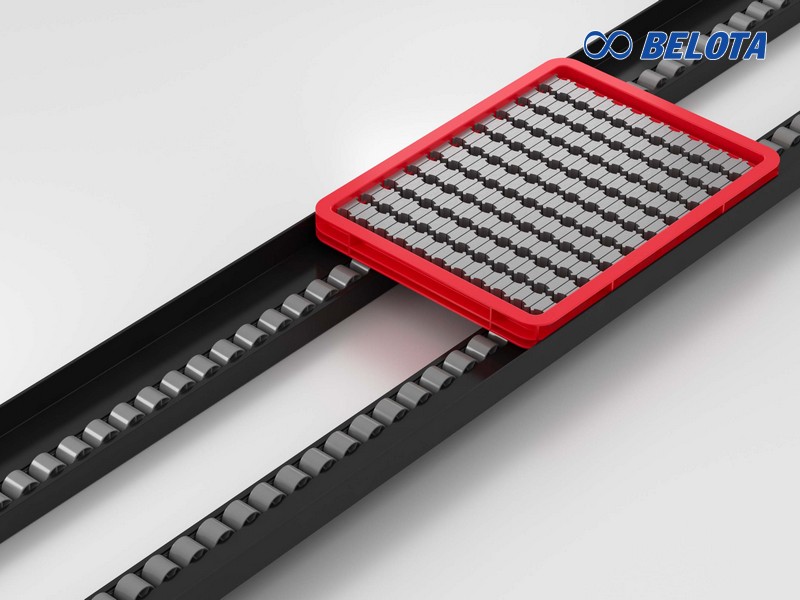

A plastic roller conveyor is a conveyor system that uses rollers made from engineering plastics such as PVC, PE, PU, or POM. When goods are placed on the roller surface, they move smoothly and continuously through manual force, gravity, or a powered drive system.

Thanks to their lightweight structure, corrosion resistance, and low noise operation, plastic roller conveyors are especially suitable for food processing, pharmaceutical production, cold storage, packaging lines, and humid or chemically exposed environments where metal rollers are prone to rust.

Structure of a Plastic Roller Conveyor

Plastic roller conveyors are designed with simple components but deliver high conveying efficiency. The overall system weight is significantly lighter than PVC, PU, or rubber belt conveyors. The basic structure includes:

-

Conveyor Frame: Made of galvanized steel, stainless steel, or aluminum profiles. The frame supports the entire system and ensures structural stability during operation.

-

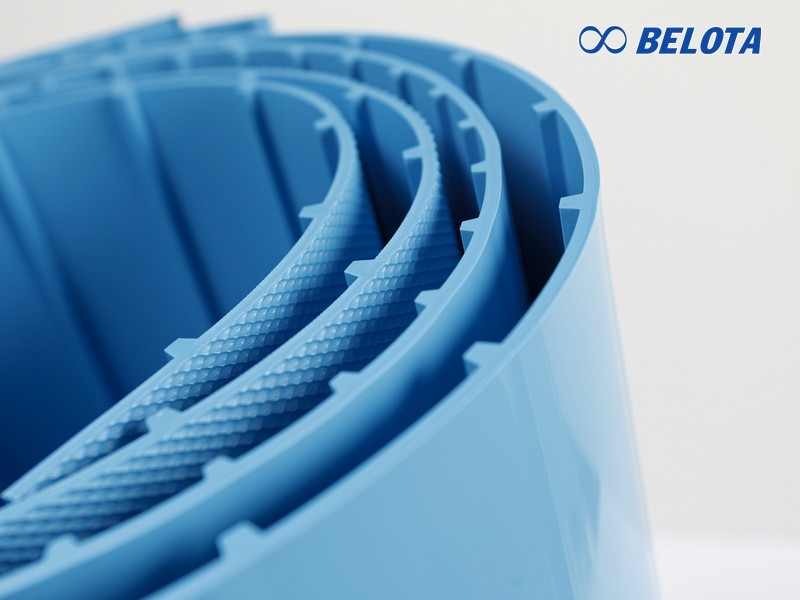

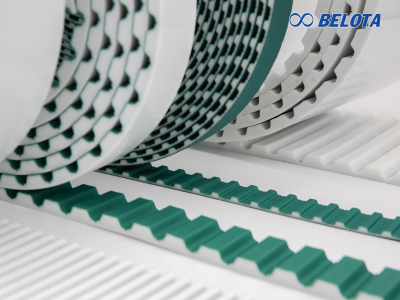

Plastic Rollers: The core component, typically manufactured from POM, PVC, PP, or HDPE. These rollers are lightweight, rust-proof, chemical-resistant, and help reduce operational noise.

-

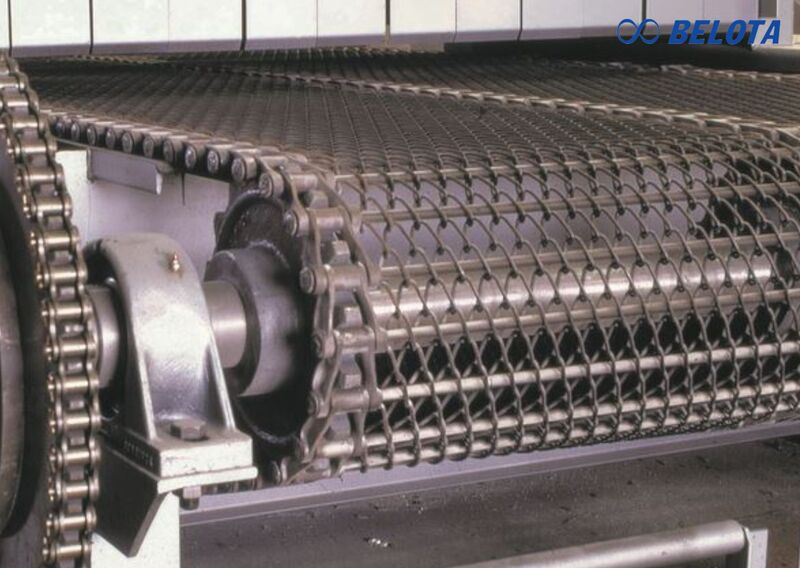

Roller Shaft: Steel or stainless steel shafts run through the rollers, enabling smooth rotation. Bearings or locking pins secure the shaft to the frame.

-

Bearings: Ensure smooth roller rotation, reduce friction, minimize wear, and extend service life, even in dusty, wet, or humid environments.

-

Support Legs & Stands: Adjustable legs can be installed to match conveyor height requirements for different production lines.

-

Optional Accessories: Sensors, side guides, guard rails, and drive motors (for powered roller conveyors).

>> See Also: Chain Roller Conveyor Solutions for Heavy Loads | Belota

General Technical Specifications of Plastic Roller Conveyors

-

Conveyor width: 400 mm – 1000 mm

-

Conveyor length: 2 m – 15 m

-

Roller diameter: Ø38 mm – Ø120 mm

-

Roller pitch: 100 mm – 300 mm

-

Load capacity: 30 – 200 kg/m

-

Roller materials: PVC, PE, PU, POM

-

Drive types: Gravity, motor-driven with chain or belt

-

Operating temperature range: -10°C to 80°C

Key Advantages of Plastic Roller Conveyors

-

Excellent corrosion resistance: Plastic rollers do not rust, making them ideal for humid environments, cold storage, and food processing industries.

-

Quiet operation: Reduced noise levels make them suitable for warehouses, electronics factories, and clean production areas.

-

Lightweight design: Easy to transport, install, and reconfigure.

-

Cost-effective solution: Lower initial investment while maintaining reliable operational performance, ideal for small and medium-sized businesses.

-

High customization: Conveyor dimensions, roller spacing, materials, and accessories can be customized to meet specific production requirements.

Common Types of Plastic Roller Conveyors

1. Gravity Roller Conveyor

Operates without a motor; rollers rotate using gravity or manual force. Suitable for light to medium loads.

2. Powered Roller Conveyor

Equipped with a motor and transmission system (chain or belt) to transport heavier loads at a controlled and stable speed.

3. Straight Roller Conveyor

Designed for linear material transport, commonly used in continuous production lines.

4. Curved Roller Conveyor

Allows product direction changes from 30° to 180°, ideal for tight spaces and corner layouts in factories or warehouses.

Applications of Plastic Roller Conveyors

-

Warehouses & Distribution Centers: Efficient movement of goods between storage areas or from trucks into warehouses.

-

Production Lines: Transporting components and finished products in compact production environments.

-

Food, Beverage & Chemical Industries: Safe handling of cartons, packaging, and containers while maintaining hygiene standards.

-

Import & Export Operations: Flexible and efficient loading and unloading of goods into containers or trucks, reducing labor costs.

Reliable Supplier of Plastic Roller Conveyors

With smooth operation, lightweight structure, and product-safe handling, Belota plastic roller conveyors are the ideal solution for modern production lines and logistics systems. We are committed to delivering:

✅ High-quality plastic rollers – Smooth surface, wear-resistant, stable conveying

✅ Quiet operation – Suitable for clean factories and warehouse environments

✅ Flexible design – Customizable length, width, roller pitch, and frame structure

✅ Product safety – No surface damage, ideal for cartons, packages, and light goods

✅ Wide industry compatibility – Logistics, food packaging, electronics, garment industries

✅ Moisture & mild chemical resistance – Reliable operation in industrial environments

✅ Easy installation & maintenance – Simple structure, quick roller replacement

✅ High cost efficiency – Long service life, low operating and maintenance costs

✅ Seamless integration – Compatible with PVC, PU, and inclined conveyor systems

📞 Contact Belota at 0917 657 946 for expert consultation and the best conveyor solution for your production line.

>> See more: Roller Conveyors | Durable Material Handling Systems