In modern production lines, especially in the food, pharmaceutical, and packaging industries - white PVC conveyor belts have become a standard choice thanks to their ability to meet strict hygiene requirements while maintaining durability and high operational efficiency.

If you are considering this conveyor belt solution for your production line, Belota will help you clearly understand its structure, technical specifications, classifications, key advantages, practical applications, and current market pricing making it easier to select the most suitable solution for your system.

Introduction to White PVC Conveyor Belts

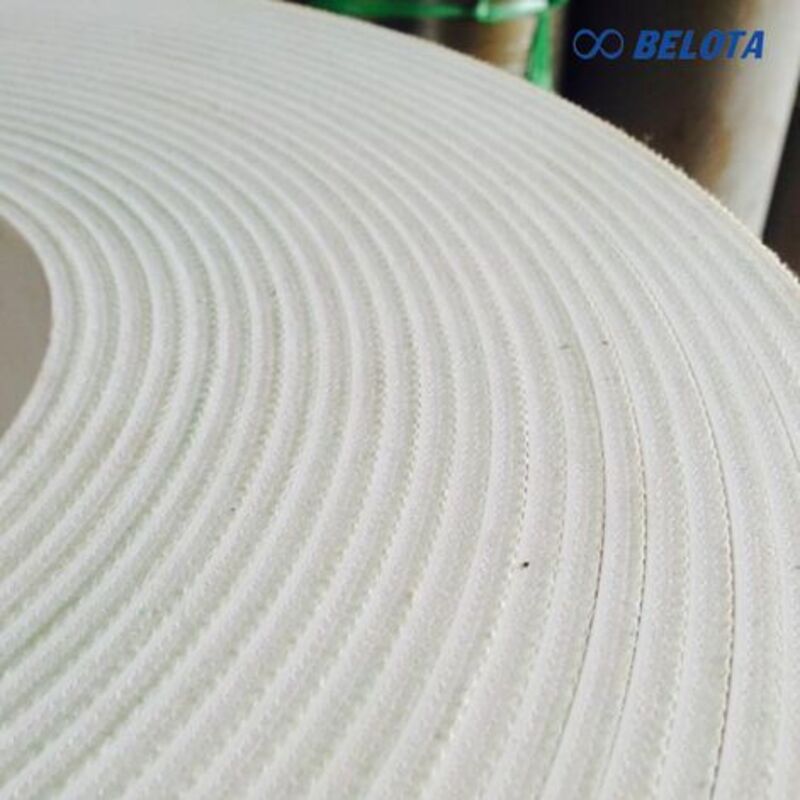

A white PVC conveyor belt is manufactured from white Polyvinyl Chloride (PVC) combined with a strong fabric reinforcement layer. It is widely used in industries that require high hygiene standards—such as food processing and pharmaceuticals thanks to its non-stick surface, antibacterial properties, and resistance to oils and grease.

The white color makes contaminants easy to detect, ensuring safety when the belt comes into direct contact with products. This belt is ideal for packaging, sorting, and conveying lines, delivering stable performance and improved productivity.

It is no coincidence that white is the standard color in the F&B (Food & Beverage) industry. Using white PVC conveyor belts offers three core benefits:

-

Absolute hygiene control: The high contrast of the white surface allows workers or AI camera systems to easily detect dirt, mold, or foreign objects.

-

Professional and clean appearance: Creates a bright, sanitary production environment—especially important when customers or partners visit the factory.

-

FDA compliance: Most high-quality white PVC belts comply with basic FDA requirements for indirect food contact.

See Also: Green PVC Conveyor Belts – Durable & Stable | BELOTA

Structure of White PVC Conveyor Belts

-

Standard dimensions: W300 × L1200 × H750 (customized on request)

-

White / light-gray PVC belt: Common thicknesses 1mm – 2mm – 3mm – 5mm – 7mm; excellent abrasion resistance and longer lifespan than rubber belts

-

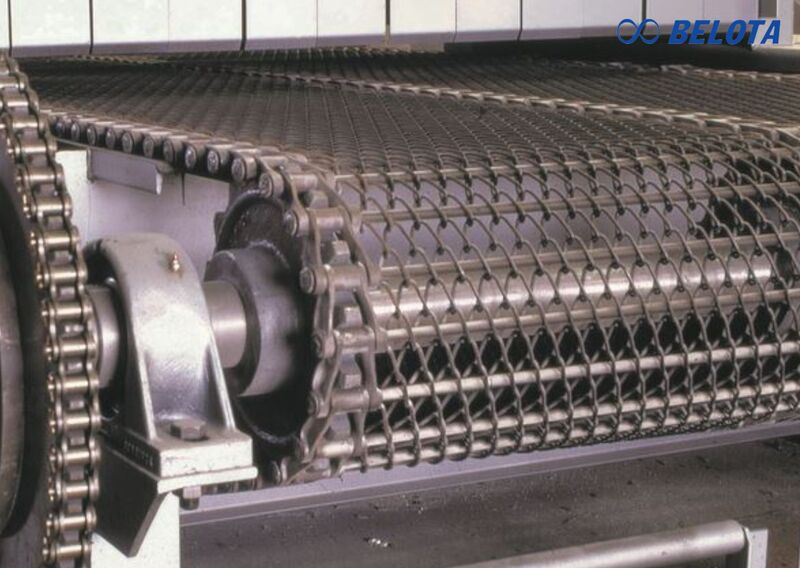

Frame: Aluminum profile, powder-coated steel, or stainless steel

-

Drive system: Chain drive or belt drive

-

Motor: 60W / 220V geared motor (ZD), optional speed controller or inverter

-

Drive rollers: Stainless steel, galvanized steel, or aluminum

Diameters: Ø50 – Ø60 – Ø76 – Ø89 – Ø102 mm -

Electrical system: Control panel, cable tray, power sockets, adjustable leveling feet

-

Optional accessories: Sensors, timers, photoelectric sensors, PLC for automation

Standard Technical Specifications

Below are typical specifications of white PVC conveyor belts commonly used in Vietnam:

-

Material: PVC (Polyvinyl Chloride) + fabric reinforcement

-

Color: White

-

Common thicknesses: 1mm, 2mm, 3mm, 4mm, 5mm

-

Surface types:

-

Smooth / glossy: Easy to clean, slightly higher grip

-

Matte / textured: Better anti-slip performance for smooth products

-

-

Operating temperature: Stable from -10°C to +80°C

-

Weight: 1 – 9 kg/m²

-

Tensile strength: ≥ 80 N/mm & ≥ 680 N/mm

-

Coefficient of friction: Low

-

Roller diameter compatibility: 40 mm to 320 mm

-

Special features: Oil-resistant and anti-static options available

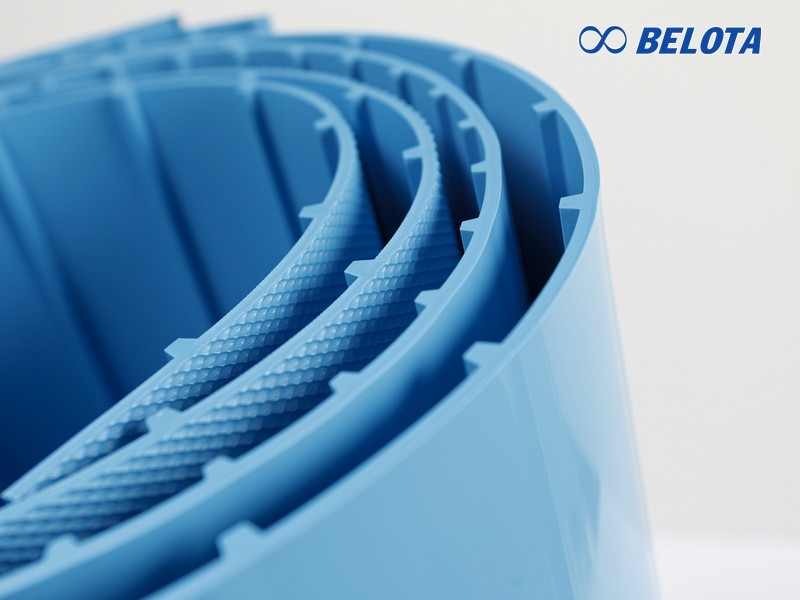

Classification of White PVC Conveyor Belts

By Structure & Thickness

By number of fabric plies:

-

2-ply (Light duty): Most common (≈80%), lightweight, suitable for small rollers (Ø60 mm)

-

3-ply (Medium duty): Better tensile strength, reduced elongation

-

4-ply (Heavy duty): Suitable for long conveyors and higher loads

By thickness:

-

Most common: 2mm, 3mm

-

Other options: 4mm, 5mm, 6mm up to 8mm

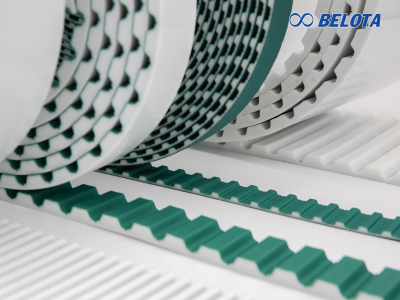

By Surface Type

-

Smooth / glossy surface: Easy cleaning, ideal for food, confectionery, and pharmaceuticals

-

Textured / patterned surface: Patterns such as diamond, dot, rib, or cleated surfaces increase friction and prevent slipping, ideal for inclined conveying

See Also: White PU conveyor belts - Efficient solutions from Belota

Key Advantages of White PVC Conveyor Belts

-

Easy hygiene inspection: White color highlights dirt and foreign matter instantly

-

Non-stick surface: Smooth and easy to clean

-

Antibacterial & food-safe: Meets FDA standards for food handling

-

Excellent resistance: Water, oil, chemicals, acids, and UV rays

-

High durability: Resistant to abrasion, tearing, delamination, and deformation

-

Heat resistance & anti-static options: Stable performance in controlled temperatures

-

Quiet operation: Low noise, smooth and stable conveying

Industrial Applications

-

Food processing: Meat, seafood, fruits, vegetables—safe, hygienic conveying

-

Medical & pharmaceutical: Syringes, masks, medical devices, creams, liquids

-

Electronics manufacturing: Anti-static options for LEDs, ICs, electronic components

-

Packaging lines: Fast and efficient handling of small to medium products

-

Garment industry: Conveying clothing, shoes, and accessories between processes

Important Notes When Using White PVC Conveyor Belts

-

Ensure belt quality: Check fabric layers, thickness, and surface finish

-

Precision splicing: Straight cuts and proper joint techniques prevent tracking issues

-

Uniform belt circumference: Avoid tapering during splicing to ensure stable operation

-

Low elongation: Minimizes tension loss and extends belt lifespan

These factors directly affect durability and overall system efficiency.

Market Price Reference for White PVC Conveyor Belts

White PVC Belt Material (without installation)

| Thickness | Fabric Structure | Reference Price (VND/m²) |

|---|---|---|

| 1 mm | 1 ply | 370,000 – 420,000 |

| 2 mm | 1 ply | 400,000 – 450,000 |

| 3 mm | 2 ply | 550,000 – 650,000 |

| 4 mm | 2 ply | 800,000 – 900,000 |

| 5 mm | 3 ply | 880,000 – 950,000 |

Note: Prices are for reference only and may vary based on belt width, order quantity, joint type, and market conditions.

Complete Conveyor Systems (frame + motor + installation)

| Conveyor Type | Basic Configuration | Reference Price (VND/set) |

|---|---|---|

| Mini PVC conveyor | Simple structure, light load | 6,000,000 – 10,000,000 |

| Standard PVC conveyor | Steel/aluminum frame, geared motor | 10,000,000 – 20,000,000 |

| Food-grade PVC conveyor | Inverter, sensors, high hygiene requirements | From 20,000,000 |

Trusted Supplier of White PVC Conveyor Belts

Stable operation, long-term efficiency, and international safety standards - Belota white PVC conveyor belts are the preferred choice for modern factories.

We commit to providing:

✅ Genuine, high-quality materials

✅ Optimized performance & energy efficiency

✅ Flexible custom design

✅ Food-safe & hygienic solutions

✅ Professional technical consultation

✅ Nationwide installation & maintenance

✅ Chemical and temperature resistance

✅ Long service life & cost savings

📞 Contact Belota at 0917 657 946 today to receive expert consultation and the most suitable conveyor solution for your production line.

See Also: PVC Conveyor Belts – Durable & Custom Solutions | BELOTA