Nowadays, rubber conveyor belts are widely chosen by many businesses thanks to their outstanding performance and ability to meet the demands of almost all industries, from mining, construction, and cement to food processing and airports. If you are looking for an industrial conveyor solution, rubber conveyor belts are a reliable and cost-effective option.

In this article, Belota will help you gain a comprehensive understanding of rubber conveyor belts, including their types, characteristics, applications, and updated price references on the market.

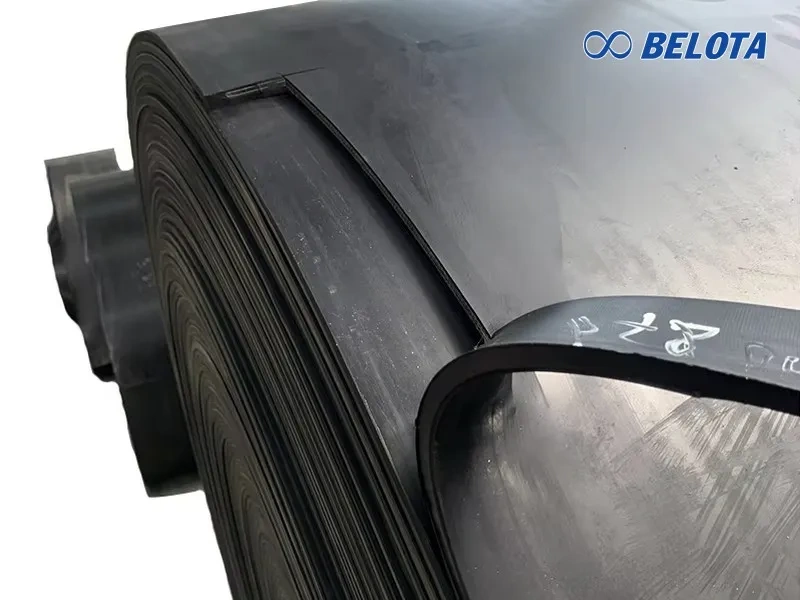

A rubber conveyor belt is a commonly used industrial conveyor belt in mining, cement, coal, agricultural products, and material manufacturing industries. With a durable rubber cover mounted on a frame system with rollers at both ends, it forms a smooth and reliable conveying solution with excellent abrasion resistance, tensile strength, and impact resistance.

Thanks to their high durability, stable conveying performance, and ability to operate in harsh environments, rubber conveyor belts help businesses improve productivity, reduce manual labor, and lower operating costs while ensuring continuous production.

A standard rubber conveyor belt system typically includes the following components:

The most important component, directly responsible for transporting materials. Its structure usually consists of:

Manufactured from stainless steel, powder-coated steel, SUS304 stainless steel, or aluminum profiles. The frame supports the entire system, ensuring stability and minimizing vibration during operation.

Help reduce friction and keep the belt running smoothly, including:

Maintains proper belt tension, including:

Designed to reduce material buildup, prevent belt misalignment, and extend belt life:

Protective covers, belt trackers, feeding systems, auxiliary rollers, anti-adhesive rollers, safety sensors (belt misalignment, speed sensors, emergency switches), lubrication systems, and support stands.

Key technical parameters include:

See Also: PVC Conveyor Belts Manufacturer & Supplier | BELOTA

Rubber conveyor belts are widely used due to their superior performance:

Designed for conveying high-temperature materials such as clinker, hot stones, and metal products. Available in several heat resistance grades ranging from 100°C up to short-term exposure of 300°C.

Applications: Cement plants, steel mills, brick factories, fertilizer plants, power plants.

Featuring a flat, smooth surface suitable for general conveying. They offer quiet operation, high durability, and easy cleaning.

Applications: Mining, cement, agriculture, wood processing, fertilizer, dry food handling.

Designed with V-shaped cleats to prevent material slippage on inclined conveyors.

Applications: Inclined conveying, agriculture, coal, construction materials, logistics.

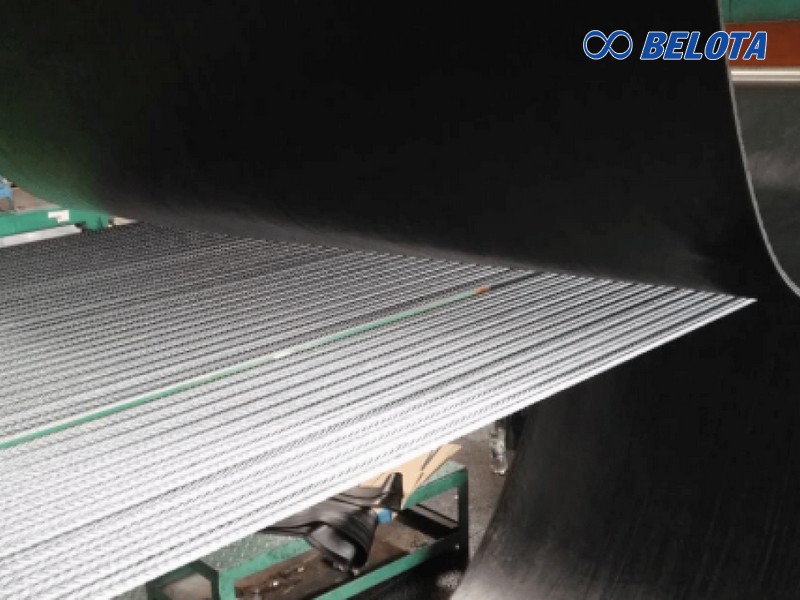

Built with steel reinforcement for extremely heavy loads, long distances, and high tension.

Applications: Mining, cement plants, fertilizer factories, inclined conveyor systems.

Compact belts designed for light-duty conveying in small production lines.

Applications: Electronics, food packaging, pharmaceuticals, light assembly lines

Rubber conveyor belt prices depend on size, structure, material type, and application requirements. Market prices generally range from 200,000 – 800,000 VND per meter, depending on specifications.

Belota provides updated pricing with competitive rates and technical support tailored to each project.

| Rubber Conveyor Belt Type | Common Width Range (mm) | Cover Thickness / Construction | Reference Price [VND/m] |

|---|---|---|---|

| Smooth Rubber Conveyor Belt | 300 – 700 | Rubber cover with EP/NN fabric carcass | 220,000 – 400,000 |

| V-Cleated Rubber Conveyor Belt | 400 – 800 | Rubber cover with V-shaped cleats | 300,000 – 550,000 |

| Sidewall Rubber Conveyor Belt | 500 – 900 | Rubber cover with sidewalls (plastic or rubber) | 450,000 – 700,000 |

| Bucket Rubber Conveyor Belt | 500 – 1,000 | Rubber cover with molded buckets | 500,000 – 750,000 |

| Fabric Ply Rubber Conveyor Belt | 400 – 1,200 | Multiple EP/NN fabric plies | 250,000 – 500,000 |

| Steel Cord Rubber Conveyor Belt | 800 – 1,400 | Steel cord reinforcement with rubber cover | 450,000 – 800,000 |

| White Rubber Conveyor Belt (Food / Sugar Grade) | 500 – 1,000 | White rubber, hygienic & food-grade compliant | 300,000 – 600,000 |

| Heat-Resistant Rubber Conveyor Belt | 600 – 1,200 | Heat-resistant rubber with multiple plies | 400,000 – 750,000 |

| Chemical-Resistant Rubber Conveyor Belt | 500 – 1,100 | Chemical-resistant rubber compound | 350,000 – 650,000 |

| Trough Rubber Conveyor Belt | 700 – 1,200 | Fabric ply or steel cord with suitable rubber cover | 400,000 – 700,000 |

Key selection factors include:

With over 8 years of experience, Belota is a trusted supplier of industrial conveyor belt solutions in Vietnam. We provide high-quality rubber conveyor belts, competitive pricing, fast nationwide delivery, and professional technical services including measurement, splicing, installation, and after-sales support.

Contact Belota:

See Also: Latest Conveyor Belt Price List All Types | Free Consultation