B Section V-Belts are among the most widely used classical V-belts in industrial applications thanks to their high power transmission capability, stable pulley grip, and heavy-load performance. With a thick, robust structure and clearly defined technical standards, B Section V-belts are commonly found in both industrial and agricultural machinery. If you are looking for technical specifications and a standard size reference table, the content below will help you understand everything clearly and accurately.

Introduction to B Section V-Belts

B Section V-Belts are classical V-belts with a larger cross-section than A Section belts, specifically designed for high-power and heavy-duty transmission systems such as generators, air compressors, crushers, industrial motors, and many other machines.

With a standard V-shaped profile, B Section V-belts provide:

- Strong pulley grip

- Stable power transmission

- Reduced slippage

- Long service life under continuous operation

Other common names:

- B Section V-Belt

- B Type V-Belt

B Section V-belts are widely used across various production and manufacturing industries.

>> See Also: A Section V-Belt Supplier | Full Size Range – Belota

Standard Technical Specifications of B Section V-Belts

| Parameter | Standard Value |

|---|---|

| Top Width | 17 mm |

| Height | 11 mm |

| V-Angle | 40° |

| Length | Defined by belt code (e.g. B60 = 60 inches) |

Notes on belt length:

- Li: Inside length

- Ld / La: Nominal or reference length

Length conversion depends on manufacturer standards

Length code examples:

- B60 = 60 inches ≈ 1524 mm

- B72 = 72 inches ≈ 1829 mm

B Section V-Belt Size Reference Table by Product Code

| Product Code | Length (mm) | Width | Thickness | V-Angle |

|---|---|---|---|---|

| B20 | 505 | 16.7 | 11 | 40 |

| B21 | 530 | 16.7 | 11 | 40 |

| B22 | 560 | 16.7 | 11 | 40 |

| B23 | 585 | 16.7 | 11 | 40 |

| B24 | 610 | 16.7 | 11 | 40 |

| B25 | 635 | 16.7 | 11 | 40 |

| B26 | 660 | 16.7 | 11 | 40 |

| B27 | 685 | 16.7 | 11 | 40 |

| B28 | 710 | 16.7 | 11 | 40 |

| B29 | 735 | 16.7 | 11 | 40 |

| B30 | 760 | 16.7 | 11 | 40 |

| B31 | 785 | 16.7 | 11 | 40 |

| B32 | 815 | 16.7 | 11 | 40 |

| B33 | 836 | 16.7 | 11 | 40 |

| B34 | 865 | 16.7 | 11 | 40 |

| B34 1/2 | 875 | 16.7 | 11 | 40 |

| B35 | 889 | 16.7 | 11 | 40 |

| B36 | 914 | 16.7 | 11 | 40 |

| B37 | 940 | 16.7 | 11 | 40 |

| B37 1/2 | 950 | 16.7 | 11 | 40 |

| B38 | 965 | 16.7 | 11 | 40 |

| B38 1/2 | 975 | 16.7 | 11 | 40 |

| B39 | 990 | 16.7 | 11 | 40 |

| B40 | 1.016 | 16.7 | 11 | 40 |

| B41 | 1.04 | 16.7 | 11 | 40 |

| B42 | 1.06 | 16.7 | 11 | 40 |

| B42 1/2 | 1.075 | 16.7 | 11 | 40 |

| B43 | 1.09 | 16.7 | 11 | 40 |

| B44 | 1.12 | 16.7 | 11 | 40 |

| B45 | 1.14 | 16.7 | 11 | 40 |

| B46 | 1.168 | 16.7 | 11 | 40 |

| B47 | 1.2 | 16.7 | 11 | 40 |

| B48 | 1.22 | 16.7 | 11 | 40 |

| B48 1/2 | 1.225 | 16.7 | 11 | 40 |

| B49 | 1.25 | 16.7 | 11 | 40 |

| B50 | 1.27 | 16.7 | 11 | 40 |

| B51 | 1.3 | 16.7 | 11 | 40 |

| B52 | 1.32 | 16.7 | 11 | 40 |

| B53 | 1.35 | 16.7 | 11 | 40 |

| B54 | 1.372 | 16.7 | 11 | 40 |

| B55 | 1.4 | 16.7 | 11 | 40 |

| B56 | 1.422 | 16.7 | 11 | 40 |

| B57 | 1.45 | 16.7 | 11 | 40 |

| B58 | 1.475 | 16.7 | 11 | 40 |

| B59 | 1.5 | 16.7 | 11 | 40 |

| B60 | 1.525 | 16.7 | 11 | 40 |

| B61 | 1.55 | 16.7 | 11 | 40 |

| B62 | 1.575 | 16.7 | 11 | 40 |

| B63 | 1.6 | 16.7 | 11 | 40 |

| B64 | 1.625 | 16.7 | 11 | 40 |

| B65 | 1.65 | 16.7 | 11 | 40 |

| B66 | 1.675 | 16.7 | 11 | 40 |

| B67 | 1.7 | 16.7 | 11 | 40 |

| B68 | 1.725 | 16.7 | 11 | 40 |

| B69 | 1.75 | 16.7 | 11 | 40 |

| B70 | 1.775 | 16.7 | 11 | 40 |

| B71 | 1.8 | 16.7 | 11 | 40 |

| B72 | 1.825 | 16.7 | 11 | 40 |

| B73 | 1.85 | 16.7 | 11 | 40 |

| B74 | 1.88 | 16.7 | 11 | 40 |

| B75 | 1.9 | 16.7 | 11 | 40 |

| B76 | 1.93 | 16.7 | 11 | 40 |

| B77 | 1.95 | 16.7 | 11 | 40 |

| B78 | 1.975 | 16.7 | 11 | 40 |

| B79 | 2 | 16.7 | 11 | 40 |

| B80 | 2.03 | 16.7 | 11 | 40 |

| B81 | 2.06 | 16.7 | 11 | 40 |

| B82 | 2.08 | 16.7 | 11 | 40 |

| B83 | 2.1 | 16.7 | 11 | 40 |

| B83 1/2 | 2.12 | 16.7 | 11 | 40 |

| B84 | 2.135 | 16.7 | 11 | 40 |

| B85 | 2.16 | 16.7 | 11 | 40 |

| B86 | 2.2 | 16.7 | 11 | 40 |

| B87 | 2.22 | 16.7 | 11 | 40 |

| B88 | 2.24 | 16.7 | 11 | 40 |

| B89 | 2.26 | 16.7 | 11 | 40 |

| B90 | 2.285 | 16.7 | 11 | 40 |

| B91 | 2.31 | 16.7 | 11 | 40 |

| B92 | 2.335 | 16.7 | 11 | 40 |

| B93 | 2.36 | 16.7 | 11 | 40 |

| B94 | 2.38 | 16.7 | 11 | 40 |

| B94 1/2 | 2.4 | 16.7 | 11 | 40 |

| B95 | 2.41 | 16.7 | 11 | 40 |

| B96 | 2.435 | 16.7 | 11 | 40 |

| B96 1/2 | 2.45 | 16.7 | 11 | 40 |

| B97 | 2.465 | 16.7 | 11 | 40 |

| B98 | 2.5 | 16.7 | 11 | 40 |

| B99 | 2.525 | 16.7 | 11 | 40 |

| B100 | 2.54 | 16.7 | 11 | 40 |

| B101 | 2.56 | 16.7 | 11 | 40 |

| B102 | 2.6 | 16.7 | 11 | 40 |

| B103 | 2.625 | 16.7 | 11 | 40 |

| B104 | 2.65 | 16.7 | 11 | 40 |

| B105 | 2.675 | 16.7 | 11 | 40 |

| B106 | 2.7 | 16.7 | 11 | 40 |

| B107 | 2.725 | 16.7 | 11 | 40 |

| B108 | 2.75 | 16.7 | 11 | 40 |

| B109 | 2.775 | 16.7 | 11 | 40 |

| B110 | 2.8 | 16.7 | 11 | 40 |

| B111 | 2.825 | 16.7 | 11 | 40 |

| B112 | 2.85 | 16.7 | 11 | 40 |

| B113 | 2.875 | 16.7 | 11 | 40 |

| B114 | 2.9 | 16.7 | 11 | 40 |

| B115 | 2.925 | 16.7 | 11 | 40 |

| B116 | 2.95 | 16.7 | 11 | 40 |

| B117 | 2.975 | 16.7 | 11 | 40 |

| B118 | 3 | 16.7 | 11 | 40 |

| B119 | 3.025 | 16.7 | 11 | 40 |

| B120 | 3.05 | 16.7 | 11 | 40 |

| B121 | 3.075 | 16.7 | 11 | 40 |

| B122 | 3.1 | 16.7 | 11 | 40 |

| B123 | 3.125 | 16.7 | 11 | 40 |

| B124 | 3.15 | 16.7 | 11 | 40 |

| B125 | 3.175 | 16.7 | 11 | 40 |

| B126 | 3.2 | 16.7 | 11 | 40 |

| B127 | 3.225 | 16.7 | 11 | 40 |

| B128 | 3.25 | 16.7 | 11 | 40 |

| B129 | 3.275 | 16.7 | 11 | 40 |

| B130 | 3.3 | 16.7 | 11 | 40 |

| B131 | 3.325 | 16.7 | 11 | 40 |

| B132 | 3.35 | 16.7 | 11 | 40 |

| B133 | 3.375 | 16.7 | 11 | 40 |

| B134 | 3.4 | 16.7 | 11 | 40 |

| B135 | 3.425 | 16.7 | 11 | 40 |

| B136 | 3.45 | 16.7 | 11 | 40 |

| B137 | 3.475 | 16.7 | 11 | 40 |

| B138 | 3.5 | 16.7 | 11 | 40 |

| B139 | 3.525 | 16.7 | 11 | 40 |

| B140 | 3.55 | 16.7 | 11 | 40 |

| B141 | 3.575 | 16.7 | 11 | 40 |

| B142 | 3.6 | 16.7 | 11 | 40 |

| B143 | 3.625 | 16.7 | 11 | 40 |

| B144 | 3.65 | 16.7 | 11 | 40 |

| B145 | 3.675 | 16.7 | 11 | 40 |

| B146 | 3.7 | 16.7 | 11 | 40 |

| B147 | 3.734 | 16.7 | 11 | 40 |

| B148 | 3.75 | 16.7 | 11 | 40 |

| B149 | 3.785 | 16.7 | 11 | 40 |

| B150 | 3.8 | 16.7 | 11 | 40 |

| B151 | 3.835 | 16.7 | 11 | 40 |

| B152 | 3.861 | 16.7 | 11 | 40 |

| B153 | 3.886 | 16.7 | 11 | 40 |

| B154 | 3.912 | 16.7 | 11 | 40 |

| B155 | 3.925 | 16.7 | 11 | 40 |

| B156 | 3.962 | 16.7 | 11 | 40 |

| B157 | 3.988 | 16.7 | 11 | 40 |

| B158 | 4 | 16.7 | 11 | 40 |

| B159 | 4.039 | 16.7 | 11 | 40 |

| B160 | 4.065 | 16.7 | 11 | 40 |

| B161 | 4.089 | 16.7 | 11 | 40 |

| B162 | 4.115 | 16.7 | 11 | 40 |

| B163 | 4.14 | 16.7 | 11 | 40 |

| B164 | 4.166 | 16.7 | 11 | 40 |

| B165 | 4.19 | 16.7 | 11 | 40 |

| B166 | 4.216 | 16.7 | 11 | 40 |

| B167 | 4.25 | 16.7 | 11 | 40 |

| B168 | 4.267 | 16.7 | 11 | 40 |

| B169 | 4.293 | 16.7 | 11 | 40 |

| B170 | 4.32 | 16.7 | 11 | 40 |

| B171 | 4.343 | 16.7 | 11 | 40 |

| B173 | 4.394 | 16.7 | 11 | 40 |

| B175 | 4.445 | 16.7 | 11 | 40 |

| B177 | 4.5 | 16.7 | 11 | 40 |

| B178 | 4.521 | 16.7 | 11 | 40 |

| B180 | 4.57 | 16.7 | 11 | 40 |

| B182 | 4.623 | 16.7 | 11 | 40 |

| B185 | 4.7 | 16.7 | 11 | 40 |

| B186 | 4.724 | 16.7 | 11 | 40 |

How to Read B Section V-Belt Codes Correctly

1. Belt code structure

A B Section V-belt code consists of one letter + numbers:

- B: Belt cross-section (17 mm top width, 11 mm height, 40° angle)

- Numbers: Belt length in inches

Examples:

- B60 → 60 inches

- B85 → 85 inches

- B100 → 100 inches

2. Quick inch-to-mm conversion

1 inch = 25.4 mm

Examples:

- B60 = 1525 mm

- B85 = 2160 mm

- B100 = 2540 mm

3. Common length symbols

- Li: Inside length

- La / Ld: Nominal or outside length

Examples:

- B72 Li: 72-inch inside length

- B85 Ld: 85-inch nominal length

If no symbol is specified, the belt uses the default standard length.

Key Advantages of B Section V-Belts

High transmission efficiency

Thanks to the larger cross-section and 40° V-angle, B Section belts provide excellent pulley grip, ensuring strong, stable power transmission with minimal slippage—even during continuous operation.

Durability and wear resistance

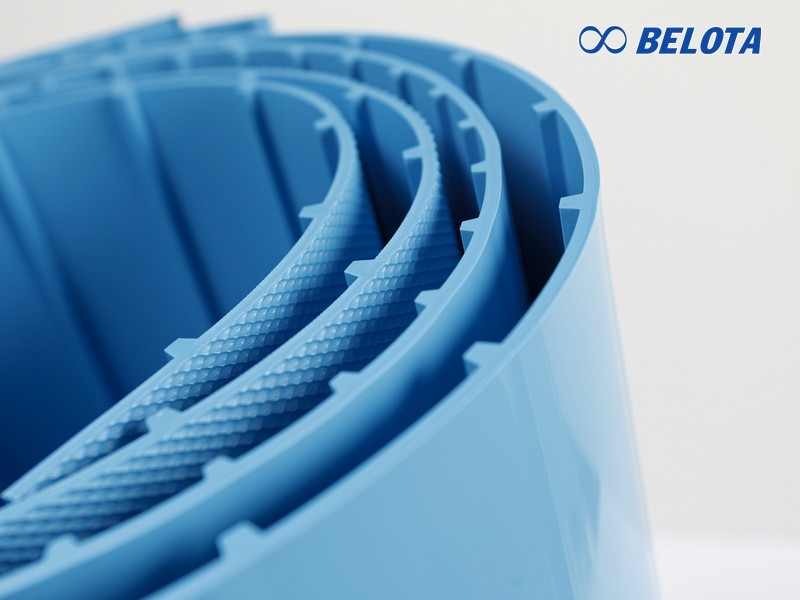

Manufactured from synthetic rubber, tensile cords, and abrasion-resistant fabric layers, these belts perform reliably in harsh environments and resist cracking, hardening, and elongation over time.

Heavy-load capability

Compared to A Section belts, B Section V-belts are thicker and stronger, making them ideal for heavy-duty industrial machinery operating at high loads and speeds without deformation or belt drop.

Applications of B Section V-Belts in Industry

B Section V-belts are widely used due to their high load capacity, strong grip, and stable operation, including:

- Agricultural machinery: rice mills, water pumps, crushers, threshers

- Industrial machines & motors: industrial fans, air compressors, woodworking machines

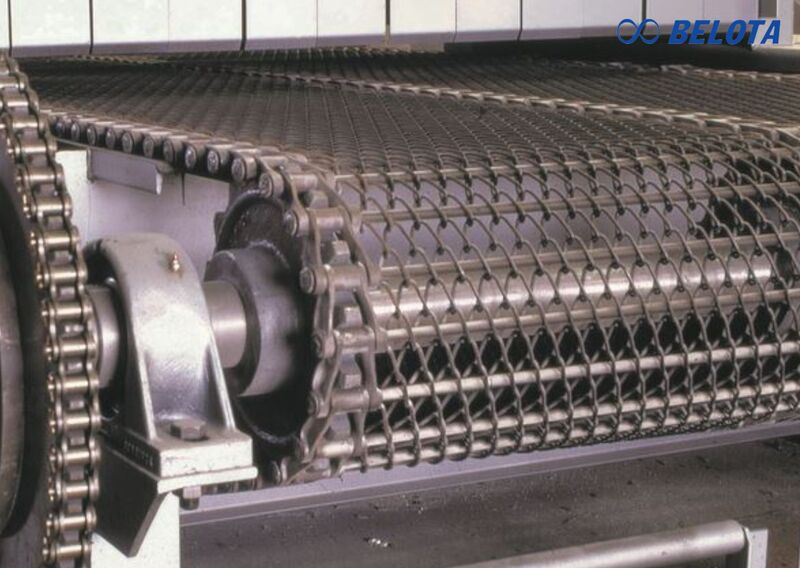

- Conveyor systems: driving pulleys for stable material handling under heavy loads

- Continuous production equipment: factory lines requiring long operating hours without overheating or belt stretching

- High-power machinery: applications demanding higher strength than A Section belts

>> See Also: Gates V-Belts | Official Supplier, Full Range – Belota

FAQ – Frequently Asked Questions About B Section V-Belts

What is a B Section V-Belt?

A B Section V-Belt is a trapezoidal power transmission belt with a 17 mm top width, 11 mm height, and a 40° angle. It is larger than A Section belts and designed for heavy-duty, continuous-operation machinery.

What machines use B Section V-Belts?

Common applications include:

- Agricultural machines: mills, pumps, crushers

- Industrial equipment: motors, compressors, fans

- Conveyor systems and production lines requiring stable heavy-load transmission

What do B60, B72, B85 mean?

These are belt length codes:

- B indicates B Section

- Numbers represent belt length in inches

- The larger the number, the longer the belt.

How often should B Section V-Belts be replaced?

Typical replacement intervals:

- 6–12 months for continuous or heavy-load operation

- 12–24 months for light or intermittent use

Replace immediately if the belt shows cracks, edge wear, excessive elongation, slippage, or abnormal noise.

Trusted Supplier of B Section V-Belts

Stable transmission, strong pulley grip, and long-lasting performance - Belota B Section V-Belts are the optimal choice for modern industrial machinery. We provide:

✅ High-quality materials – durable synthetic rubber and reinforced tensile cords

✅ Optimal transmission efficiency – reduced slippage, stable torque

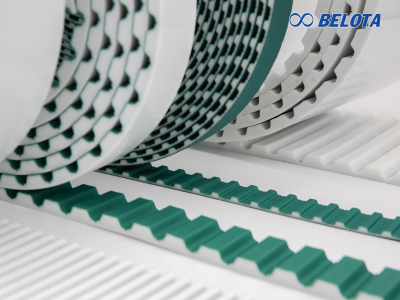

✅ Wide product range – V-belts, timing belts, PU belts, flat and round belts

✅ Custom sizing – cut-to-length based on load, speed, and pulley type

✅ Industrial-grade safety – oil-resistant, heat-resistant options

✅ Professional technical support – precise belt selection for every application

✅ Fast installation & replacement – nationwide service

✅ Reduced operating costs – less stretching, less maintenance

✅ Easy integration – compatible with pumps, compressors, CNC machines, conveyors

📞 Contact Belota at 0917 657 946 for expert consultation and the right belt solution for your system.

>> See More: Drive Belts – Full Range, High Performance & Competitive Prices