The A-section V-belt (V-Belt A) is the most widely used classical V-belt type today. It features a top width of 12.7 mm, height of 8 mm, and a 40° V-angle, providing stable power transmission and strong grip on the pulley groove. With advantages such as high load capacity, anti-slip performance, and long service life, A-section V-belts are suitable for most industrial, agricultural, and general-purpose machinery. In this article, Belota introduces the technical specifications, common sizes, and typical applications of A-section V-belts.

Introduction to A-Section V-Belt & Basic Specifications

The A-section V-belt (also known as A-type V-belt, A-profile belt, or classical V-belt A) is a traditional V-belt with a trapezoidal cross-section and the following standard dimensions:

- Top width: 12.7 mm

- Height (thickness): 8 mm

- V-angle: 40°

- Belt length:

- Defined by the belt code (e.g. A40 = 40 inches)

- Measured in inches or millimeters

- Example: A40 = 40 inches ≈ 1016 mm

>> See Also: B-Type V-Belts for Industry | High Load Capacity – Belota

Key Features of A-Section V-Belts

- V-shaped profile ensures strong pulley grip and efficient power transmission

- Excellent resistance to slipping, vibration, and noise

- High load-bearing capacity and long service life

- Suitable for a wide range of transmission speeds

- Easy replacement thanks to standardized sizes

How to Measure and Select an A-Section V-Belt

When replacing an A-section V-belt, you can follow these simple methods:

- Measure the belt length directly on the pulley using a flexible tape to determine the inside length (Li)

- Check the belt code printed on the belt surface (if still visible)

- Refer to the standard size chart to select the correct belt

A-Section V-Belt Size Chart

Belota supplies a wide range of A-section V-belts from A15 to A217, all featuring the same standard cross-section:

| Product Code | Inside Length (mm) | Reference Length (mm) | Top Width (mm) | Height (mm) | V-Angle (°) |

|---|---|---|---|---|---|

| A15 | 381 | 415 | 12.7 | 8 | 40 |

| A16 | 406 | 440 | 12.7 | 8 | 40 |

| A17 | 430 | 466 | 12.7 | 8 | 40 |

| A18 | 455 | 491 | 12.7 | 8 | 40 |

| A19 | 480 | 517 | 12.7 | 8 | 40 |

| A20 | 505 | 542 | 12.7 | 8 | 40 |

| A21 | 530 | 567 | 12.7 | 8 | 40 |

| A22 | 560 | 593 | 12.7 | 8 | 40 |

| A23 | 585 | 618 | 12.7 | 8 | 40 |

| A23 1/2 | 600 | 631 | 12.7 | 8 | 40 |

| A24 | 610 | 644 | 12.7 | 8 | 40 |

| A25 | 635 | 669 | 12.7 | 8 | 40 |

| A26 | 660 | 694 | 12.7 | 8 | 40 |

| A26 1/2 | 670 | 707 | 12.7 | 8 | 40 |

| A27 | 685 | 720 | 12.7 | 8 | 40 |

| A27 1/2 | 700 | 732 | 12.7 | 8 | 40 |

| A28 | 710 | 745 | 12.7 | 8 | 40 |

| A29 | 735 | 771 | 12.7 | 8 | 40 |

| A29 1/2 | 750 | 783 | 12.7 | 8 | 40 |

| A30 | 760 | 796 | 12.7 | 8 | 40 |

| A31 | 785 | 821 | 12.7 | 8 | 40 |

| A31 1/2 | 800 | 834 | 12.7 | 8 | 40 |

| A32 | 815 | 847 | 12.7 | 8 | 40 |

| A32 1/2 | 825 | 859 | 12.7 | 8 | 40 |

| A33 | 836 | 872 | 12.7 | 8 | 40 |

| A34 | 865 | 898 | 12.7 | 8 | 40 |

| A34 1/2 | 875 | 910 | 12.7 | 8 | 40 |

| A35 | 889 | 923 | 12.7 | 8 | 40 |

| A35 1/2 | 900 | 936 | 12.7 | 8 | 40 |

| A36 | 914 | 948 | 12.7 | 8 | 40 |

| A36 1/2 | 927 | 961 | 12.7 | 8 | 40 |

| A37 | 940 | 974 | 12.7 | 8 | 40 |

| A37 1/2 | 950 | 986 | 12.7 | 8 | 40 |

| A38 | 965 | 999 | 12.7 | 8 | 40 |

| A38 1/2 | 975 | 1,012 | 12.7 | 8 | 40 |

| A39 | 990 | 1,025 | 12.7 | 8 | 40 |

| A40 | 1,016 | 1,050 | 12.7 | 8 | 40 |

| A40 1/2 | 1,030 | 1,063 | 12.7 | 8 | 40 |

| A41 | 1,040 | 1,075 | 12.7 | 8 | 40 |

| A41 1/2 | 1,050 | 1,088 | 12.7 | 8 | 40 |

| A42 | 1,060 | 1,101 | 12.7 | 8 | 40 |

| A43 | 1,090 | 1,126 | 12.7 | 8 | 40 |

| A43 1/2 | 1,105 | 1,139 | 12.7 | 8 | 40 |

| A44 | 1,120 | 1,152 | 12.7 | 8 | 40 |

| A45 | 1,140 | 1,177 | 12.7 | 8 | 40 |

| A46 | 1,168 | 1,202 | 12.7 | 8 | 40 |

| A46 1/2 | 1,180 | 1,215 | 12.7 | 8 | 40 |

| A47 | 1,200 | 1,228 | 12.7 | 8 | 40 |

| A48 | 1,220 | 1,253 | 12.7 | 8 | 40 |

| A49 | 1,250 | 1,279 | 12.7 | 8 | 40 |

| A50 | 1,270 | 1,304 | 12.7 | 8 | 40 |

| A51 | 1,300 | 1,329 | 12.7 | 8 | 40 |

| A52 | 1,320 | 1,355 | 12.7 | 8 | 40 |

| A53 | 1,350 | 1,380 | 12.7 | 8 | 40 |

| A54 | 1,372 | 1,406 | 12.7 | 8 | 40 |

| A55 | 1,400 | 1,431 | 12.7 | 8 | 40 |

| A56 | 1,422 | 1,456 | 12.7 | 8 | 40 |

| A57 | 1,450 | 1,482 | 12.7 | 8 | 40 |

| A58 | 1,475 | 1,507 | 12.7 | 8 | 40 |

| A59 | 1,500 | 1,533 | 12.7 | 8 | 40 |

| A60 | 1,525 | 1,558 | 12.7 | 8 | 40 |

| A61 | 1,550 | 1,583 | 12.7 | 8 | 40 |

| A62 | 1,575 | 1,609 | 12.7 | 8 | 40 |

| A63 | 1,600 | 1,634 | 12.7 | 8 | 40 |

| A64 | 1,625 | 1,660 | 12.7 | 8 | 40 |

| A65 | 1,650 | 1,685 | 12.7 | 8 | 40 |

| A66 | 1,675 | 1,710 | 12.7 | 8 | 40 |

| A67 | 1,700 | 1,736 | 12.7 | 8 | 40 |

| A68 | 1,725 | 1,761 | 12.7 | 8 | 40 |

| A69 | 1,750 | 1,787 | 12.7 | 8 | 40 |

| A70 | 1,775 | 1,812 | 12.7 | 8 | 40 |

| A71 | 1,800 | 1,837 | 12.7 | 8 | 40 |

| A72 | 1,825 | 1,863 | 12.7 | 8 | 40 |

| A73 | 1,850 | 1,888 | 12.7 | 8 | 40 |

| A74 | 1,880 | 1,914 | 12.7 | 8 | 40 |

| A75 | 1,900 | 1,939 | 12.7 | 8 | 40 |

| A76 | 1,930 | 1,964 | 12.7 | 8 | 40 |

| A77 | 1,950 | 1,990 | 12.7 | 8 | 40 |

| A78 | 1,975 | 2,015 | 12.7 | 8 | 40 |

| A79 | 2,000 | 2,041 | 12.7 | 8 | 40 |

| A80 | 2,030 | 2,066 | 12.7 | 8 | 40 |

| A81 | 2,060 | 2,091 | 12.7 | 8 | 40 |

| A82 | 2,080 | 2,117 | 12.7 | 8 | 40 |

| A83 | 2,100 | 2,142 | 12.7 | 8 | 40 |

| A83 1/2 | 2,120 | 2,155 | 12.7 | 8 | 40 |

| A84 | 2,135 | 2,168 | 12.7 | 8 | 40 |

| A85 | 2,160 | 2,193 | 12.7 | 8 | 40 |

| A86 | 2,200 | 2,218 | 12.7 | 8 | 40 |

| A87 | 2,220 | 2,244 | 12.7 | 8 | 40 |

| A88 | 2,240 | 2,269 | 12.7 | 8 | 40 |

| A89 | 2,260 | 2,295 | 12.7 | 8 | 40 |

| A90 | 2,285 | 2,320 | 12.7 | 8 | 40 |

| A91 | 2,310 | 2,345 | 12.7 | 8 | 40 |

| A92 | 2,335 | 2,371 | 12.7 | 8 | 40 |

| A93 | 2,360 | 2,396 | 12.7 | 8 | 40 |

| A94 | 2,380 | 2,422 | 12.7 | 8 | 40 |

| A95 | 2,410 | 2,447 | 12.7 | 8 | 40 |

| A96 | 2,435 | 2,472 | 12.7 | 8 | 40 |

| A97 | 2,465 | 2,498 | 12.7 | 8 | 40 |

| A97 1/2 | 2,477 | 2,510 | 12.7 | 8 | 40 |

| A98 | 2,500 | 2,523 | 12.7 | 8 | 40 |

| A99 | 2,525 | 2,549 | 12.7 | 8 | 40 |

| A100 | 2,540 | 2,574 | 12.7 | 8 | 40 |

| A101 | 2,560 | 2,599 | 12.7 | 8 | 40 |

| A102 | 2,600 | 2,625 | 12.7 | 8 | 40 |

| A103 | 2,625 | 2,650 | 12.7 | 8 | 40 |

| A104 | 2,650 | 2,676 | 12.7 | 8 | 40 |

| A105 | 2,675 | 2,701 | 12.7 | 8 | 40 |

| A106 | 2,700 | 2,726 | 12.7 | 8 | 40 |

| A107 | 2,725 | 2,752 | 12.7 | 8 | 40 |

| A108 | 2,750 | 2,777 | 12.7 | 8 | 40 |

| A109 | 2,775 | 2,803 | 12.7 | 8 | 40 |

| A110 | 2,800 | 2,828 | 12.7 | 8 | 40 |

| A111 | 2,825 | 2,853 | 12.7 | 8 | 40 |

| A112 | 2,850 | 2,879 | 12.7 | 8 | 40 |

| A113 | 2,875 | 2,904 | 12.7 | 8 | 40 |

| A114 | 2,900 | 2,930 | 12.7 | 8 | 40 |

| A115 | 2,925 | 2,955 | 12.7 | 8 | 40 |

| A116 | 2,950 | 2,980 | 12.7 | 8 | 40 |

| A117 | 2,975 | 3,006 | 12.7 | 8 | 40 |

| A118 | 3,000 | 3,031 | 12.7 | 8 | 40 |

| A119 | 3,025 | 3,057 | 12.7 | 8 | 40 |

| A120 | 3,050 | 3,082 | 12.7 | 8 | 40 |

| A121 | 3,075 | 3,107 | 12.7 | 8 | 40 |

| A122 | 3,100 | 3,133 | 12.7 | 8 | 40 |

| A123 | 3,125 | 3,158 | 12.7 | 8 | 40 |

| A124 | 3,150 | 3,184 | 12.7 | 8 | 40 |

| A125 | 3,175 | 3,209 | 12.7 | 8 | 40 |

| A126 | 3,200 | 3,234 | 12.7 | 8 | 40 |

| A127 | 3,225 | 3,260 | 12.7 | 8 | 40 |

| A128 | 3,250 | 3,285 | 12.7 | 8 | 40 |

| A129 | 3,275 | 3,311 | 12.7 | 8 | 40 |

| A130 | 3,300 | 3,336 | 12.7 | 8 | 40 |

| A132 | 3,350 | 3,387 | 12.7 | 8 | 40 |

| A134 | 3,400 | 3,438 | 12.7 | 8 | 40 |

| A135 | 3,425 | 3,463 | 12.7 | 8 | 40 |

| A136 | 3,450 | 3,488 | 12.7 | 8 | 40 |

| A137 | 3,475 | 3,514 | 12.7 | 8 | 40 |

| A138 | 3,500 | 3,539 | 12.7 | 8 | 40 |

| A140 | 3,550 | 3,590 | 12.7 | 8 | 40 |

| A142 | 3,600 | 3,641 | 12.7 | 8 | 40 |

| A144 | 3,650 | 3,692 | 12.7 | 8 | 40 |

| A145 | 3,675 | 3,717 | 12.7 | 8 | 40 |

| A146 | 3,700 | 3,742 | 12.7 | 8 | 40 |

| A147 | 3,734 | 3,768 | 12.7 | 8 | 40 |

| A148 | 3,750 | 3,793 | 12.7 | 8 | 40 |

| A150 | 3,800 | 3,844 | 12.7 | 8 | 40 |

| A153 | 3,886 | 3,920 | 12.7 | 8 | 40 |

| A155 | 3,925 | 3,971 | 12.7 | 8 | 40 |

| A158 | 4,000 | 4,047 | 12.7 | 8 | 40 |

| A160 | 4,065 | 4,098 | 12.7 | 8 | 40 |

| A162 | 4,115 | 4,149 | 12.7 | 8 | 40 |

| A165 | 4,160 | 4,225 | 12.7 | 8 | 40 |

| A167 | 4,250 | 4,276 | 12.7 | 8 | 40 |

| A170 | 4,320 | 4,352 | 12.7 | 8 | 40 |

| A173 | 4,394 | 4,428 | 12.7 | 8 | 40 |

| A175 | 4,445 | 4,479 | 12.7 | 8 | 40 |

| A176 | 4,470 | 4,504 | 12.7 | 8 | 40 |

| A177 | 4,500 | 4,530 | 12.7 | 8 | 40 |

| A180 | 4,570 | 4,606 | 12.7 | 8 | 40 |

| A185 | 4,700 | 4,733 | 12.7 | 8 | 40 |

| A187 | 4,750 | 4,784 | 12.7 | 8 | 40 |

| A190 | 4,825 | 4,860 | 12.7 | 8 | 40 |

| A195 | 4,955 | 4,987 | 12.7 | 8 | 40 |

| A196 | 4,978 | 5,012 | 12.7 | 8 | 40 |

| A197 | 5,000 | 5,038 | 12.7 | 8 | 40 |

| A210 | 5,335 | 5,368 | 12.7 | 8 | 40 |

| A217 | 5,512 | 5,546 | 12.7 | 8 | 40 |

Applications of A-Section V-Belts

A-section V-belts are widely used in:

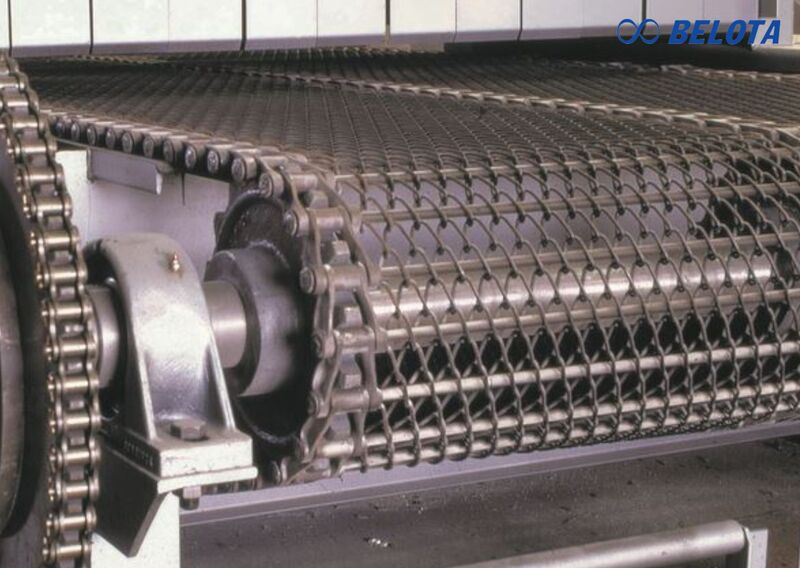

- Industrial machinery: air compressors, saws, woodworking machines, textile machines, steel rolling machines

- Automotive & motorcycles: cooling fans, water pumps, alternators

- Agriculture: rice milling machines, harvesters, water pumps, tractors

- Mechanical & general applications: drills, grinders, industrial ventilation systems

>> See More: Bando Belt Supplier | Full Range of Drive Belts – Belota

Frequently Asked Questions (FAQs)

What is the difference between A-section and B-section V-belts?

Both belong to classical V-belts but differ in size and load capacity:

- A-section: smaller cross-section (approx. 13 × 8 mm), suitable for light to medium-duty applications such as agricultural machines, water pumps, and industrial fans

- B-section: larger cross-section (approx. 17 × 11 mm), designed for higher power transmission and heavy-duty machinery

Summary:

- B-section = larger & stronger for heavy loads

- A-section = smaller, flexible, and widely used

When should the drive belt be replaced on a Honda Air Blade (AB)?

For Honda Air Blade scooters, the drive belt replacement interval is typically:

- 18,000 – 25,000 km: heavy use, high load, hot or dusty conditions

- 25,000 – 30,000 km: normal riding conditions

Signs of early replacement: reduced acceleration, vibration, abnormal noise, belt cracking, wear, or slipping.

How much does an A45 V-belt cost?

The price of an A45 V-belt depends on the brand (Gates, Mitsuboshi, Bando, Dongil, Optibelt, etc.), specifications, and supplier.

Reference price: approximately 45,000 – 130,000 VND per belt

What is an A-section V-belt?

An A-section V-belt is a classical V-belt with a standard trapezoidal cross-section (approx. 13 × 8 mm) designed to transmit power between a drive pulley and a driven pulley.

Advantages: strong pulley grip, stable power transmission, anti-slip performance, and broad applicability.

Available in many sizes from A15 to A217, making it one of the most popular and easiest belts to replace.

Trusted Supplier of A-Section V-Belts

Stable transmission, strong pulley grip, and long-lasting performance — Belota A-section V-belts are the optimal solution for industrial power transmission systems.

Belota is committed to providing:

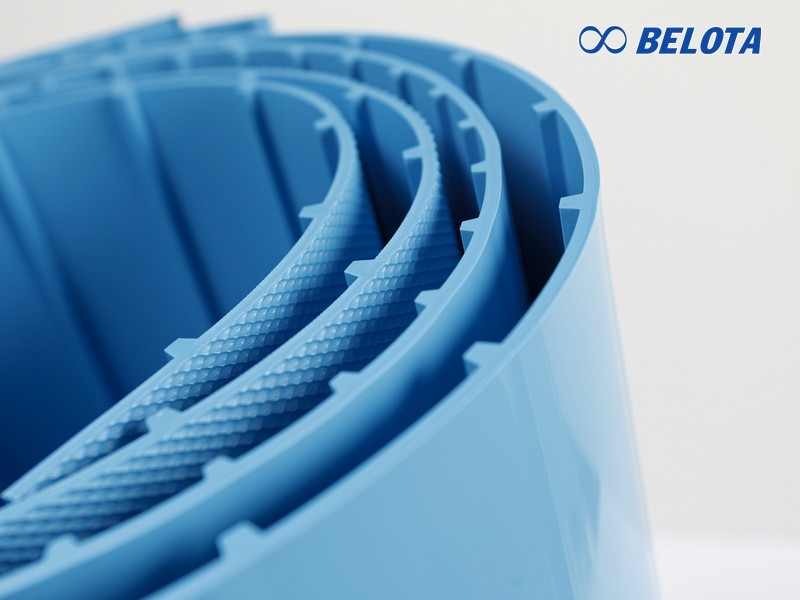

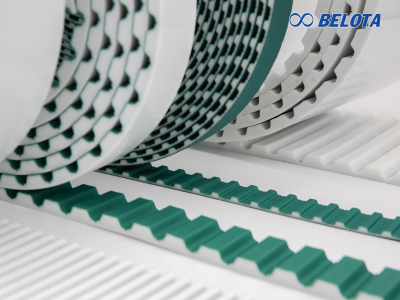

- High-quality, durable materials – premium rubber and PU compounds

- Optimized transmission efficiency – reduced slipping and stable torque

- Wide product range – V-belts, timing belts, PU belts, flat belts, round belts

- Custom sizing – cut-to-length based on load, speed, and pulley type

- Industrial-grade performance – oil-resistant, heat-resistant options

- Professional technical support – accurate belt selection for each machine

- Fast installation & replacement – nationwide service

- Reduced operating costs – less stretching, lower maintenance frequency

- Easy integration – compatible with pumps, compressors, CNC machines, conveyors, and production equipment

Contact Belota at 0917657946 for professional consultation and accurate belt selection for your system.

>> See More: Drive Belts – Full Range, High Performance & Competitive Prices