PU conveyor belts are among the most widely used conveyor belt types in modern industries thanks to their high durability, excellent abrasion resistance, and strong chemical resistance. This solution not only helps optimize production processes but also reduces maintenance costs and improves overall operational efficiency.

Let Belota guide you through the article below to better understand the outstanding advantages of this material.

A PU conveyor belt is a conveyor system made from Polyurethane (PU) belt material—a high-grade thermoplastic known for its flexibility, lightweight structure, high abrasion resistance, and superior resistance to oils and chemicals.

Compared to traditional PVC conveyor belts, PU belts offer:

Higher mechanical strength

Better heat resistance

Longer service life, especially in continuous operation environments

In addition, PU conveyor belts feature low elongation, stable power transmission, and a smooth surface that enables precise and efficient product handling. Thanks to their safe, clean, and non-toxic properties, PU belts comply with food safety standards and can be used directly in food processing lines.

See Also: PVC Conveyor Belts – Durable, Cost-Effective Solutions | BELOTA

Material: Polyurethane (PU)

Belt thickness: 0.7 – 3.0 mm (depending on model)

Colors: White, blue, green, transparent

Fabric layers: 1 – 3 plies (polyester fabric)

Hardness: 85 – 95 Shore A

Operating temperature: -20°C to +80°C (short-term up to 100°C)

Oil & grease resistance: Excellent

Abrasion resistance: Higher than PVC

Flexibility: Suitable for small pulleys

Elongation: 1 – 3% under working load

Safety standards: FDA / USDA (food-grade models)

Applications: Food processing, packaging, electronics, pharmaceuticals, logistics, sorting systems

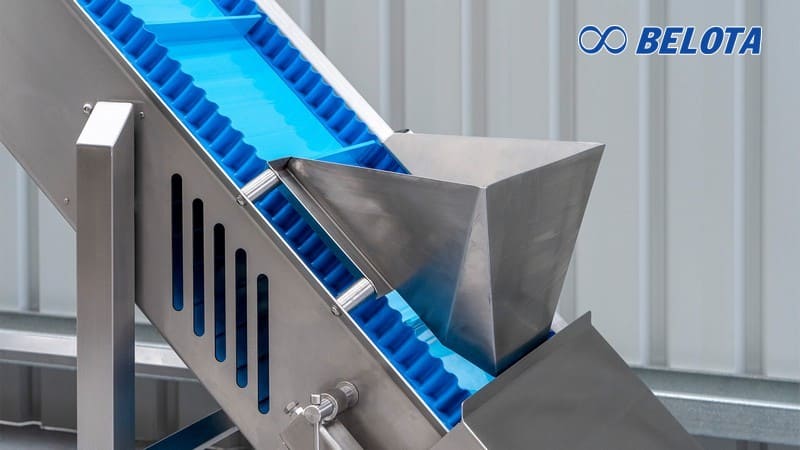

PU conveyor systems are designed with a multi-layer structure to ensure durability, flexibility, and stable operation:

PU belt: Available in white or blue, high tensile strength and load capacity

Conveyor frame: Aluminum profile, powder-coated steel, or stainless steel 304, depending on the environment

Roller system: Drive rollers, idle rollers, and support rollers, precisely machined for smooth operation

Drive system: Electric motor supplying stable power

Guiding system: Guide rails, bottom V-guide grooves, sensors to ensure accurate product positioning

PU conveyor belts combine the best properties of rubber and plastic materials, offering outstanding advantages:

High durability with excellent abrasion, impact, and pressure resistance

Flexible molding capability, reducing the risk of belt breakage

Strong resistance to oils, solvents, acids, and chemicals

Quieter operation compared to metal or rubber belts

Lightweight structure reduces energy consumption

Long service life with minimal maintenance requirements

Recyclable material helps reduce carbon emissions

Smooth white PU surface

Anti-static, low elongation, moisture and acid resistant

Higher hardness and stable conveying

Operating temperature: -35°C to 80°C

Thickness options: 0.7 – 3.0 mm

Applications: Food, pharmaceuticals, electronics

More flexible than white PU

Water resistant, high durability, stable under continuous operation

Temperature range: -35°C to 80°C

Resistant to oil and aggressive chemicals

Applications: Oil & gas, manufacturing materials, cleaning products

Special textured surface for high friction

Prevents slipping on inclined conveyors

Thickness: 1.5 – 4.0 mm

Operating temperature: -30°C to 80°C

Applications: Cartons, bags, rigid products

100% solid PU, no fabric layers

Waterproof, bacteria-resistant, extremely hygienic

Easy to clean, withstands hot water and high pressure

Operating temperature: -20°C to 90°C

Applications: Meat, seafood, dairy, pharmaceutical and cleanroom industries

Belota also supplies PU belts from leading brands such as Ammeraal Beltech, Soliflex Ammega, Forbo, Intralox, Yongli, and more.

Food & Beverage: Bakery, meat, seafood, packaged food

Pharmaceutical & Medical: Drug packaging, capsule sorting, medical devices

Electronics: PCB transport, component inspection, automated assembly

Packaging & Logistics: Labeling lines, carton handling, sorting systems

Belt misalignment: Re-adjust rollers, frame balance, and belt tension

Belt slipping: Increase tension, clean rollers, or replace worn rollers

Belt elongation: Re-tension or select thicker PU with fabric reinforcement

Surface cracking or peeling: Avoid sharp objects, excessive heat, or incompatible chemicals

Jerky operation: Check motor, inverter settings, and roller condition

See also: Rubber Conveyor Belts – Heavy-Duty & Reliable | BELOTA

Select the correct PU type for load, temperature, and chemical exposure

Ensure proper alignment and even belt tension

Avoid overloading or impact loading

Clean regularly with neutral detergents

Perform periodic maintenance on rollers, motors, and drives

Control environmental conditions and avoid excessive heat

The price of PU conveyor belts depends on many factors such as belt dimensions, material quality, structure, and supplier. Compared to other conveyor belt types, PU conveyor belts generally have a higher cost due to their superior durability, hygiene standards, and mechanical performance.

At present, the average market price of PU conveyor belts typically ranges from: VND 500,000 – 890,000 per m²

Below is an estimated reference price table for common PU conveyor belt types:

| PU Conveyor Belt Type | Thickness (mm) | Reference Price / m² (VND) |

|---|---|---|

| Flat PU – 1 fabric ply | 1.0 – 1.5 | 480,000 – 620,000 |

| Flat PU – 2 fabric plies | 1.5 – 2.0 | 620,000 – 780,000 |

| Flat PU – 3 fabric plies | 2.0 – 3.0 | 780,000 – 980,000 |

| Heat-resistant PU (80–120°C) | 1.5 – 2.5 | 950,000 – 1,250,000 |

| Rough top PU (diamond / textured surface) | 1.5 – 3.0 | 850,000 – 1,150,000 |

| PU with T-cleats / C-cleats (10–50 mm) | 1.5 – 3.0 | 1,150,000 – 1,850,000 |

| PU with sidewalls | 1.5 – 3.0 | 1,350,000 – 2,200,000 |

| Anti-static PU (ESD) | 1.5 – 2.0 | 950,000 – 1,400,000 |

| Food-grade PU (FDA certified – white) | 1.0 – 2.0 | 650,000 – 900,000 |

Note: Prices may vary depending on market conditions, order quantity, specifications, and delivery time. For an exact quotation, please contact the supplier directly.

The price of PU conveyor belts on the market can vary significantly depending on technical specifications and application requirements. Below are the most important factors that directly influence pricing:

This is the most significant factor affecting price. The thicker the belt or the more reinforcement plies it has, the higher the material cost and manufacturing complexity.

PU belts ≥ 2.0 mm or with 2–3 fabric plies typically cost 20–40% more than standard belts.

Larger belt sizes increase material consumption and production cost. Wide belts (1,200 – 1,500 mm) are always more expensive than standard widths (300 – 800 mm). Longer belt lengths also result in higher total cost.

Each PU belt type has different properties and price levels:

White PU: Most common, lower cost

Blue PU: Higher tensile strength and abrasion resistance → higher price

Rough top PU: Special surface for increased friction → higher price

Homogeneous PU: No fabric layer, extremely durable → highest price

Additional processing significantly increases belt cost, such as:

Rough, patterned, or textured surfaces

Water-drain grooves

Cleats, V-guides, or tracking guides

Sidewalls, sealed edges, or corrugated edges

These custom features can increase prices by 15–50% compared to smooth-surface PU belts.

European brands (Habasit, Chiorino, Volta): highest price, superior durability

Japanese / Korean / Taiwanese brands: mid-range price, stable quality

Chinese brands: lowest price, suitable for standard applications

Different splicing methods affect the final price:

Hot vulcanized (thermoplastic) splicing

Mechanical fastener splicing (stainless steel, hinge type)

Cleat or sidewall joint fabrication

Depending on the splicing method, additional costs typically range from VND 50,000 – 300,000 per meter.

Choosing the right PU conveyor belt supplier is critical to system performance and durability. Belota is a reputable supplier and fabricator of genuine PU conveyor belts in Vietnam, offering:

Accurate technical consultation

Custom fabrication (endless splicing, cleats, sidewalls, guides)

Genuine products with full documentation

Complete conveyor solutions (frames, pulleys, motors, installation)

Transparent warranty policies

Belota is trusted nationwide for delivering reliable quality, technical expertise, and dedicated after-sales support.

Contact Information:

Address: C63 Thoi An Residential Area, Le Thi Rieng Street, Thoi An Ward, District 12, Ho Chi Minh City, Vietnam

Hotline: +84 917 657 946

Email: info@belota.com.vn

PU is better for hygiene-critical and high-durability applications. PVC is more cost-effective for general use.

PU (Polyurethane) is a high-performance synthetic polymer offering flexibility, abrasion resistance, oil resistance, and long service life.

Is polyurethane suitable for conveyor belts?

Yes. PU is one of the best materials for conveyor belts, especially in food, pharmaceutical, and high-speed industrial applications.

Related: Latest Conveyor Belt Price List – Updated 01/2026 | Full Range | Free Technical Consultation