Roller conveyor belts are one of the most important material handling systems widely used across various industries. With a simple yet highly efficient design, this conveyor solution helps optimize transportation processes, reduce manual labor, and improve overall operational efficiency. Let Belota guide you through the article below to gain a deeper understanding of the outstanding features of roller conveyor systems.

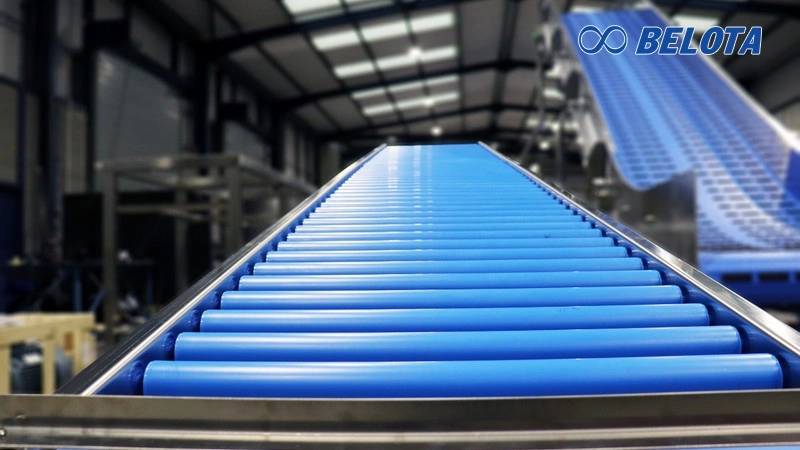

A roller conveyor belt is a material handling system consisting of multiple rollers connected together to support and transport products in industrial environments. It is suitable for conveying goods ranging from light to heavy loads.

Depending on operational requirements, rollers can operate freely (gravity rollers) or be driven by motors through chains or belts. In addition, the dual-seal bearing system effectively prevents dust and water from entering the bearings, ensuring long service life and stable performance even in harsh working conditions.

Roller conveyor belts are designed to ensure smooth operation – high durability – minimal maintenance, making them suitable for both light-duty and heavy-duty applications. A complete roller conveyor system typically consists of the following components:

Frame: Manufactured from stainless steel, powder-coated steel, or aluminum profiles, offering high rigidity and resistance to corrosion and chemicals.

Rollers:

Drive rollers made of aluminum or galvanized steel

Support rollers made of stainless steel or galvanized steel

Roller shafts: Machined with chamfered ends, threaded holes, keyways, or grooves for secure bolt fixing.

Bearing & sealing system: High-quality bearings with protective seals for long service life in dusty or wet environments.

Roller surface options: Galvanized steel, rubber-coated, plastic-coated, or PU-coated surfaces.

Common roller types: Straight rollers, plastic rollers, stainless steel rollers, self-aligning rollers.

Control system (optional): Sensors, PLC, inverters (VFD), and automation components.

>> See Also: Plastic Conveyor Belts – Durable & Reliable | Belota

Typical technical parameters include:

Roller diameter: Ø25 – Ø89 mm

Shell thickness: 1.2 – 3.0 mm

Roller length: 150 – 1,200 mm (customized)

Roller materials: Galvanized steel, stainless steel 304, PVC/PU plastic

Shaft diameter: 8 – 20 mm (threaded, keyed, or hexagonal shafts)

Roller pitch: 50 – 150 mm (depending on product size)

Frame material: Powder-coated steel, stainless steel, aluminum

Load capacity: 20 – 200 kg/m (depending on roller and frame design)

Drive types: Gravity roller, belt-driven, chain-driven, powered roller

Conveying speed: 5 – 60 m/min

Surface options: Galvanized, rubber-coated, PU-coated, anti-slip plastic

Control system (optional): Sensors, PLC, frequency inverter

Easy to relocate and reconfigure with minimal labor

Efficient horizontal conveying over long distances

Simple structure with cost-effective investment

Adjustable during operation to suit production needs

Low friction, high durability, long service life

Precision-manufactured rollers ensure smooth operation with low vibration and noise

Chain-driven roller conveyors use motorized chain transmission to ensure stable and powerful conveying. Typically manufactured from stainless steel or heavy-duty steel, they offer high load capacity and corrosion resistance. A distinctive feature is the sprocket-mounted drive roller combined with standard bearing rollers.

Plastic roller conveyors are lightweight, easy to install, and cost-effective. With high friction surfaces, they ensure stable product movement while minimizing misalignment. When combined with stainless steel shafts and bearings, they perform well in humid or chemically aggressive environments and are easy to clean and maintain.

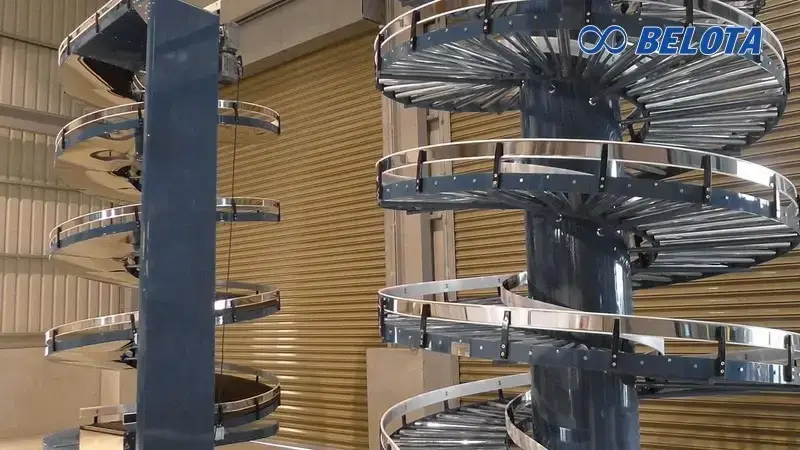

Curved roller conveyors are designed with turning angles of 45°, 60°, 90°, or 180°, making them ideal for space-constrained layouts where straight conveyors are not feasible. Built with high-strength steel or stainless steel frames and friction-enhanced rollers, they improve material flow efficiency in complex production lines.

>> See Also: Conveyor Belt Manufacturer & Supplier | Belota

Roller conveyor belts are widely used across many industries due to their flexibility, durability, and low operating cost:

Logistics & Warehousing: Carton boxes, parcels, pallets for sorting and loading

Manufacturing lines: Transferring components and semi-finished products

Food & Beverage industry: Stainless steel or plastic rollers for hygienic environments

Garment & footwear: Transporting trays, fabric rolls, packaged goods

Electronics: Conveying circuit boards and sensitive components

Wood & furniture: Handling MDF boards, plywood, and heavy panels

Seafood & chemical industries: Corrosion-resistant rollers for wet environments

Airports & postal services: Luggage and parcel sorting systems

Cold storage: Stainless steel or plastic rollers for low-temperature operation

Roller conveyor systems offer competitive pricing while ensuring high performance and durability. Prices vary depending on materials, dimensions, structure, and customization requirements.

| Roller / Conveyor Type | Specifications | Reference Price (VND/m) |

|---|---|---|

| Galvanized steel roller | Ø34 – Ø60, 1.2–2.0 mm | 150,000 – 350,000 |

| Stainless steel roller | Ø38 – Ø60, 1.2–2.0 mm | 250,000 – 480,000 |

| Rubber-coated roller | Ø42 – Ø60 | 320,000 – 520,000 |

| PVC plastic roller | Ø32 – Ø50 | 120,000 – 260,000 |

| Gravity roller conveyor | Steel/Inox frame | 1,500,000 – 3,200,000 |

| Chain-driven roller conveyor | 1–2 chain strands | 3,500,000 – 6,500,000 |

| Belt-driven roller conveyor | Motorized | 3,200,000 – 5,800,000 |

| Curved roller conveyor | 45° – 180° | 3,800,000 – 7,000,000 |

| Heavy-duty roller conveyor | 200–1,000 kg load | 5,500,000 – 9,000,000 |

Roller material: Galvanized steel, stainless steel, PVC/PU plastic

Roller diameter & thickness: Larger and thicker rollers increase load capacity and cost

Conveyor type: Gravity vs. powered (chain/belt-driven)

System dimensions: Length, width, and roller pitch

Required load capacity: Heavier loads require stronger rollers and frames

Frame material: Stainless steel is more expensive than coated steel

Brand & component quality: Premium bearings and rollers increase durability and price

Customization: Adjustable legs, side guides, sensors, speed control, automation

Belota is a leading provider of roller conveyor design, manufacturing, and installationin Vietnam. With experienced engineers and modern workshops, Belota delivers optimized, durable, and cost-effective material handling solutions for factories and warehouses.

Why Choose Belota?

High-quality roller conveyors customized to actual load requirements

Professional technical consultation and cost-optimized solutions

Transparent and competitive pricing

Fast production and installation schedules

Long-term warranty and on-site technical support

Custom fabrication and system upgrades

Contact Information:

Load capacity depends on roller diameter, shell thickness, shaft size, and roller pitch.

Plastic rollers: 5–30 kg

Galvanized steel rollers: 30–150 kg

Stainless steel & powered rollers: up to 200–500 kg (custom design)

Gravity rollers: Cost-effective, suitable for flat-bottom products

Powered rollers: Required for controlled speed, long distances, or heavy loads

Typically calculated as 1/3 of the product base length to ensure smooth operation.

Usually 5–12 days, depending on size, type, and customization.

Yes. Stainless steel rollers and frames meet HACCP hygiene standards and resist corrosion.