Felt conveyor belts are a specialized type of conveyor belt widely used in industries that require superior surface protection for products, such as textiles, printing, electronics, woodworking, and food processing.

With a soft surface structure, high friction coefficient, and excellent heat resistance, felt conveyor belts enable gentle material handling, minimize scratches, and help maintain the appearance and quality of products throughout the production process.

This makes felt conveyor belts an optimal solution for conveyor systems that demand high precision, safety, and operational stability.

A felt conveyor belt is a specialized conveyor belt designed with a soft felt-covered surface to meet the transportation needs of sensitive and delicate products.

The felt material can be made from synthetic fibers (such as polyester) or natural fibers (such as wool or cotton), which are tightly compressed to form a surface that is both soft and sufficiently high in friction.

Thanks to these properties, felt conveyor belts provide excellent product protection, minimizing scratches, cracks, or damage during conveying. They are an ideal choice for manufacturing industries that require high safety standards and superior product aesthetics.

Băng tải nỉ được thiết kế với bề mặt phủ nỉ mềm

See more: Plastic Conveyor Belts – Durable & Reliable | Belota

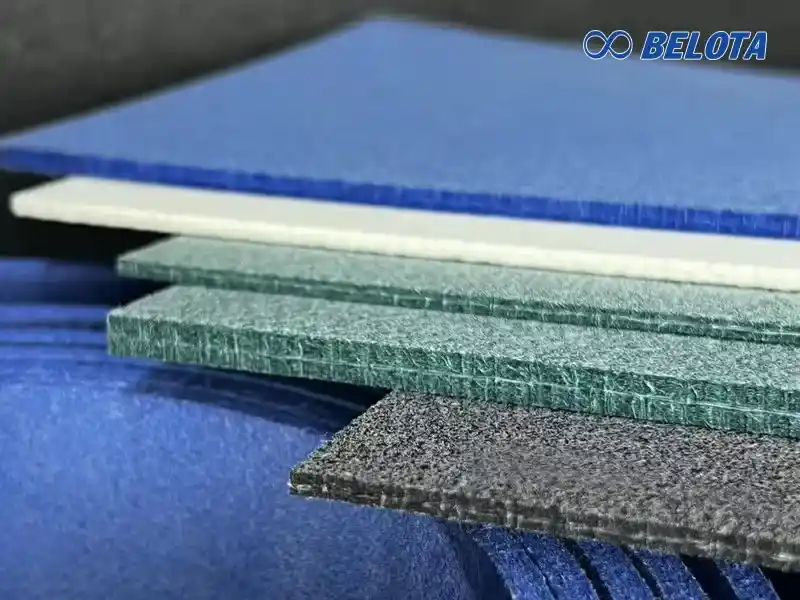

Felt conveyor belts feature a multi-layer construction to ensure durability, load capacity, and stable performance. The main components include:

The most critical component, determining friction and product protection.

Densely compressed felt creates a smooth, soft surface that minimizes scratches.

Some felt types are specially treated for anti-static, water resistance, and chemical resistance.

Located beneath the felt layer, enhancing strength and tensile resistance.

Typically made from woven cotton, polyester, nylon, or synthetic fabrics.

Helps maintain overall belt stability during operation.

Uses specialized industrial adhesives to securely bond the felt layer to the base layer.

Offers excellent heat resistance, water resistance, and strong adhesion, ensuring a unified belt structure.

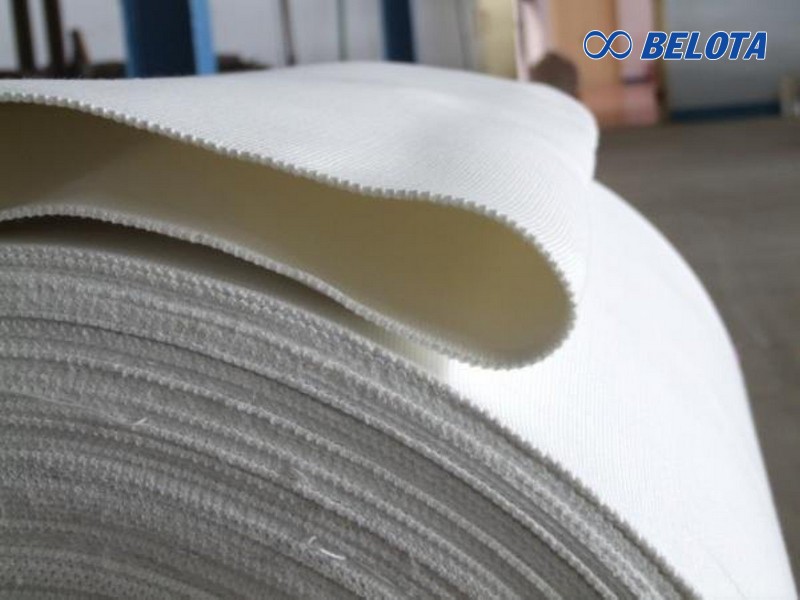

Low elongation (approximately 1%) and relatively thick construction, suitable for demanding production environments.

High-quality felt materials meeting international standards, with flame-retardant and anti-static properties.

Stable operation within a temperature range of -10°C to 80°C, with heat resistance up to 100–180°C depending on requirements.

Available in multiple colors: green, white, black, to suit various applications.

Minimum pulley diameter:

40–60 mm for forward transfer

60–80 mm for reverse bending

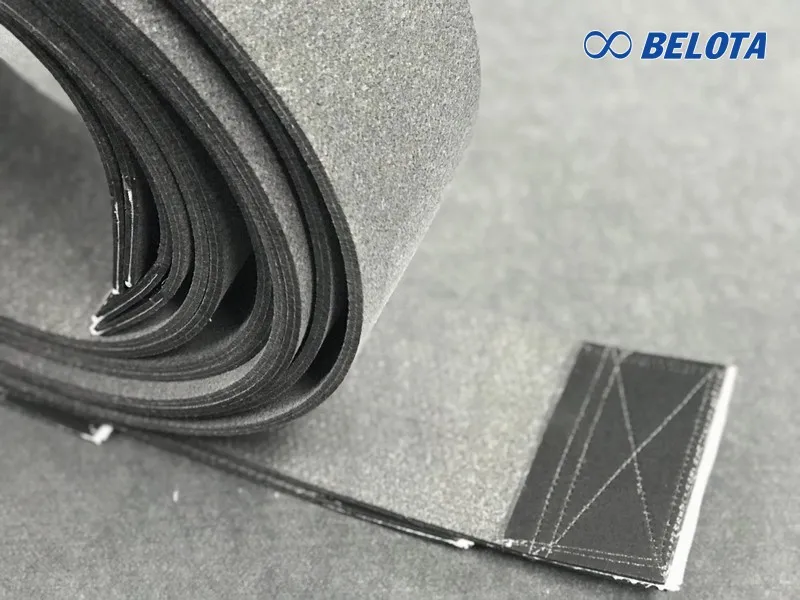

Steel fastener joint: minimum 80 mm

Băng tải nỉ được thiết kế chuyên biệt với nhiều lớp vật liệu nhằm đảm bảo độ bền

| Item | Reference Value |

|---|---|

| Felt layer thickness | 1 – 2 mm |

| Belt width | 20 – 1500 mm |

| Belt length | 20 – 2000 mm |

| Total belt thickness | 0.8 – 1.8 mm (some types: 4 – 12 mm) |

| Minimum pulley diameter | 60 mm |

| Maximum load | 20 kg/cm |

| Operating temperature | -10°C → 80°C (up to 100 – 180°C) |

| Elongation | ~1% |

| Colors | Green, white, black |

The most common type, made from synthetic polyester fibers.

Made from natural wool fibers, offering superior softness and absorption.

Manufactured from natural cotton fibers.

Made from heat-resistant Nomex fibers.

Single-layer felt conveyor belts: Suitable for light loads.

Multi-layer felt conveyor belts: Combined with additional reinforcement layers to enhance strength and load capacity.

Endless felt conveyor belts: Seamless design for continuous and stable operation.

Anti-static felt conveyor belts: Ideal for electronics manufacturing to protect sensitive components.

Heat-resistant felt conveyor belts: Designed for high-temperature operating environments.

Abrasion-resistant felt conveyor belts: Reinforced for harsh working conditions.

PU/PVC-coated felt conveyor belts: Additional PU or PVC coating for resistance to water, oil, and chemicals.

White felt conveyor belts: Typically polyester-based, widely used across industries.

Green felt conveyor belts: Similar properties to white felt, easier line identification.

Gray felt conveyor belts: Made from various materials depending on application needs.

Nomex felt conveyor belts (yellow/brown): Designed for high-temperature applications.

Soft surface: Minimizes scratches and impact, ideal for fragile products such as glass, ceramics, and electronic components.

High friction: Excellent anti-slip performance, even on inclined conveyors.

Quiet operation: Smooth running reduces vibration and noise, improving the working environment.

Material diversity: Available in polyester, wool, cotton, Nomex, and more.

High durability: Strong abrasion resistance extends service life and reduces maintenance costs.

Flexible design: Custom widths, thicknesses, grooves, or ribs to improve grip and airflow.

Simple structure: Easy installation, replacement, and cleaning, saving time and operating costs.

Felt conveyor belts are widely used across many industries due to their protective properties and stable performance:

Textile industry: Conveying fabrics, yarns, and finished garments without surface damage.

Printing industry: Transporting paper in printing and photocopying machines without ink smearing.

Electronics industry: Anti-static conveying of sensitive electronic components.

Woodworking industry: Handling processed wood and furniture without surface damage.

Food industry: Conveying dry food products and packaged goods.

Other industries: Leather, ceramics, metallurgy (heat-resistant applications), and more.

Belota is a trusted supplier of felt conveyor belts, widely chosen by businesses for consistent quality and professional service. Belota products are manufactured to high standards and tailored to conveyor systems requiring durability, grip, and heat resistance.

Why Choose Belota?

Guaranteed quality – durable materials with excellent abrasion and heat resistance.

Custom fabrication – cutting, splicing, and heat pressing to exact specifications.

Professional technical support – expert consultation for selecting the right felt type.

Strict quality inspection – ensuring thickness, elongation, and load capacity meet standards.

Fast delivery nationwide.

Competitive pricing – optimized costs for businesses.

📞 Contact Belota Hotline: +84 917 657 946 for detailed consultation and the best quotation.

Felt conveyor belts are an optimal conveying solution for industries that require superior surface protection, high friction, and stable operation. With a wide range of materials, structures, and functional options, they effectively meet demands from light-duty production to high-temperature environments.

Belota proudly delivers high-quality felt conveyor belts, custom-fabricated and rigorously inspected, helping businesses optimize operational efficiency and reduce maintenance costs. Contact us today to find the most suitable conveyor belt solution for your production line.

See more: Conveyor Belts Manufacturer & Supplier | Belota